Cartoners

Cartoning is an indispensable part of the total packaging system,

and we offer a variety of cartoners suited to each specification.

Available Models

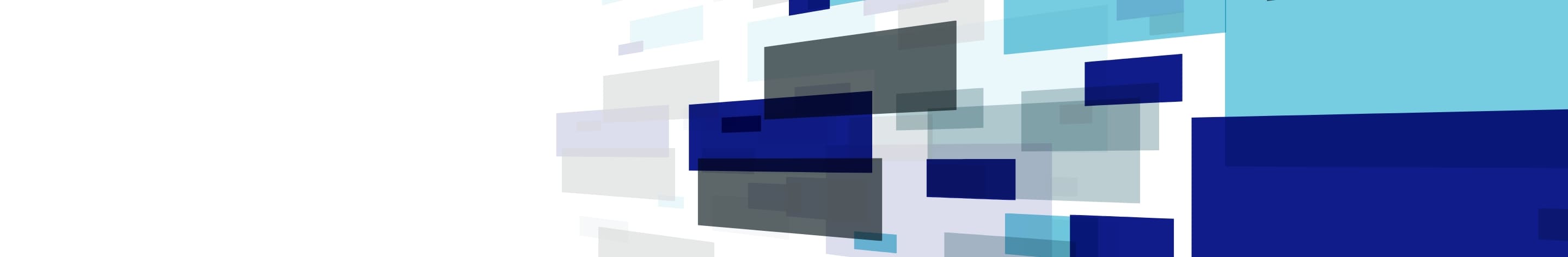

- RC-1000:Wraparound cartoner

- RCD-25: Inner box wraparound cartoner

- RCS-300: Inner box wraparound cartoner

- ASC-300:One-touch box cartoner

- C3-20:Gluing and sealing machine

- C3-20T:Gluing and sealing machine

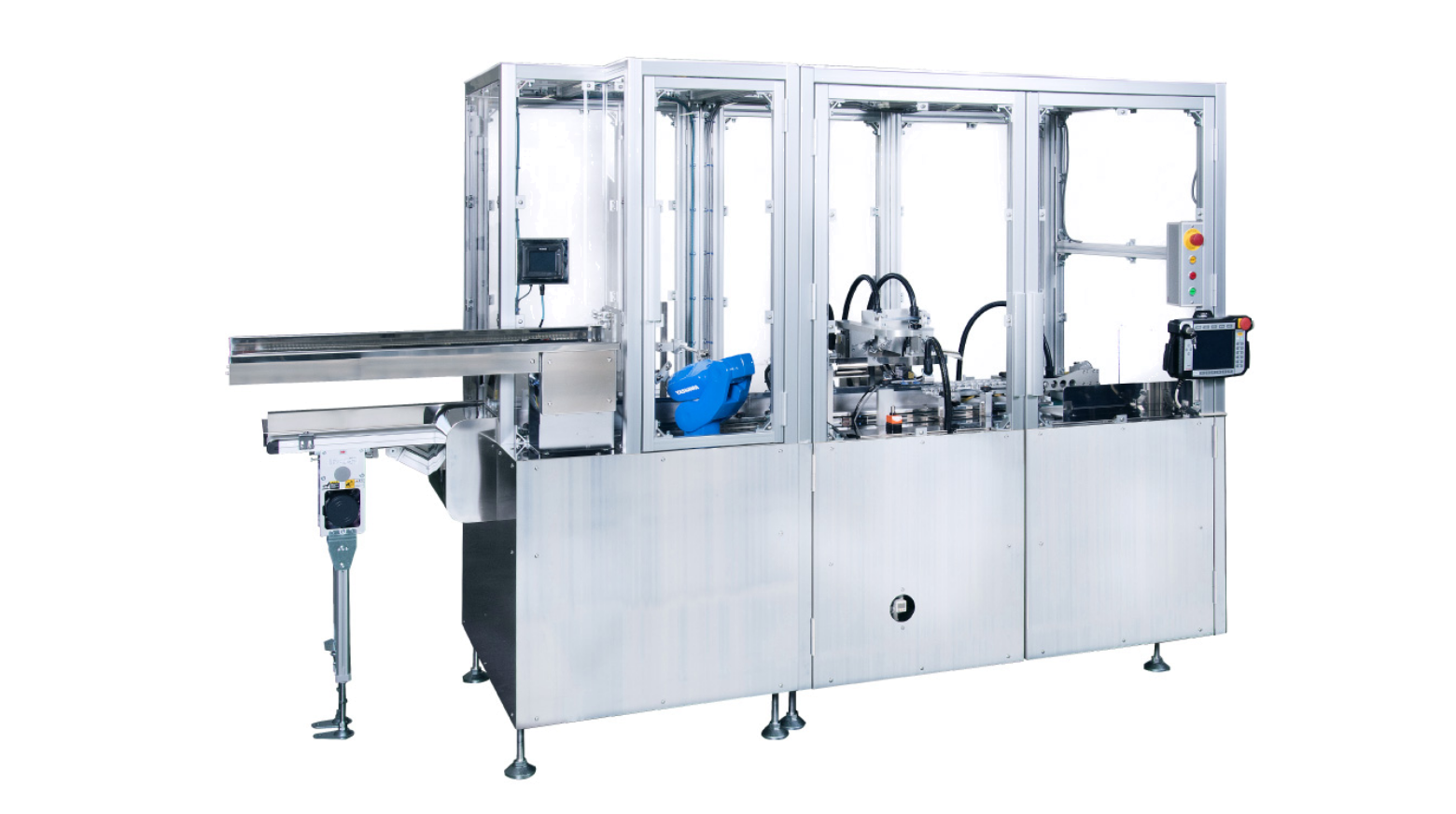

- SC-7000:Intermittent cartoner

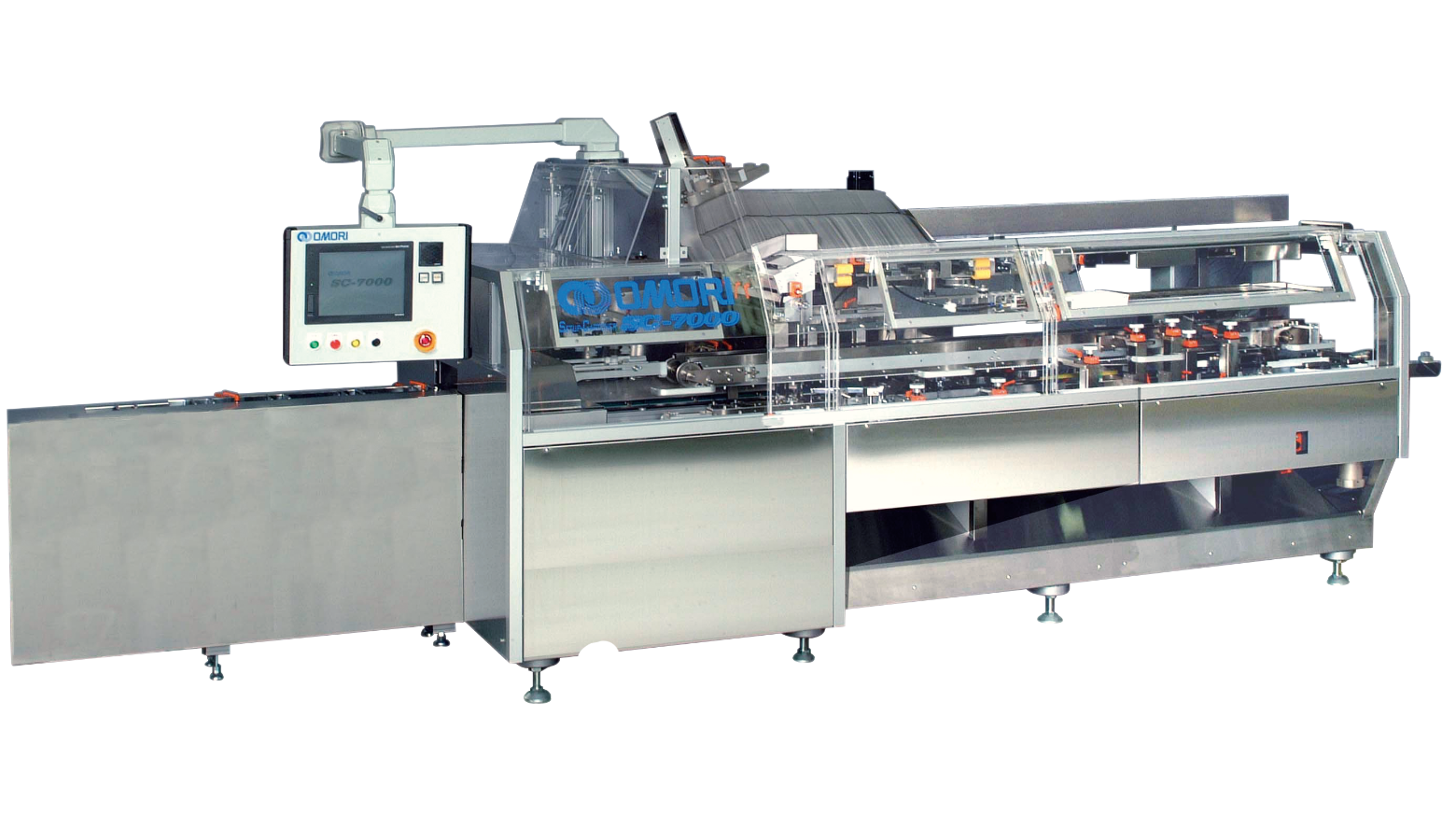

- SC-30:Intermittent end-load set-up cartoner

- Box Forming and Sealing Machines:Carton formers / Closer formers

- Heat-sealable Carton Forming Machine:Heat-seal Carton Former

- SCP-300:Pillow box cartoner

- X1 SERIES:Intermittent cartoner

- VC-2000:Vertical cartoner for pharmaceutical packaging

Product Specification Comparison Table

| Model | RC-1000 | RCS-300 | SC-30 | C3-20 | C3-20T | Carton formers / Closer formers | Heat-seal Carton Former | SCP300 |

|---|---|---|---|---|---|---|---|---|

| Speed (MAX) | 100 cartons / min. | 30 cartons / min. | 35 cartons / min. | 20 cartons / min. | 40 cartons / min. | 60 cartons / min. | 50 cartons / min. | 30 cartons / min. |

| Box making method / box type |

Wrap around | Wrap around | Intermittent end-load | One-touch boxes | One-touch boxes | Tray Dust flap Charlotte Style |

Tray | Pillow boxes |

| Sealing method | Hot melt | Hot melt | Hot-melt glue or flap insertion | Outer gluing and sealing | Outer gluing and sealing | Carton formers: Hot melt glue, lock, heat seal Closer formers: Hot melt glue |

Heat seal | Folding, hot-melting, and taping |

| Case size (width/height/length) |

MAX.85mm /MAX.60mm /MAX.135mm |

130mm~260mm /60mm~120mm /120mm~180mm |

80mm~260mm /25mm~120mm /110mm~185mm |

40mm~200mm /75mm~200mm /70mm~200mm |

40mm~150mmv/80mm~150mm /100mm~160mm |

76mm~150mm /25mm~51mm /89mm~400mm |

100~260mm /15~50mm /80~180mm |

|

| Approximate machine length (including manual feed conveyor) |

4900mm | 3400㎜ | 3000mm | 1600mm | 2900mm | 8100mm | 2300㎜ | 2100mm |