To pack your products securely and reliably

At OMORI, our entire staff has worked together to create a great number of packaging machines.

Each packing machine development process is truly a meticulous custom-made process that carefully addresses individual customer requirements.

Teamwork among our mechanical design, electrical design, manufacturing, and sales departments is crucial to this process. Therefore, we’d like to introduce two Project Stories about how new machines were created.

STORY.1

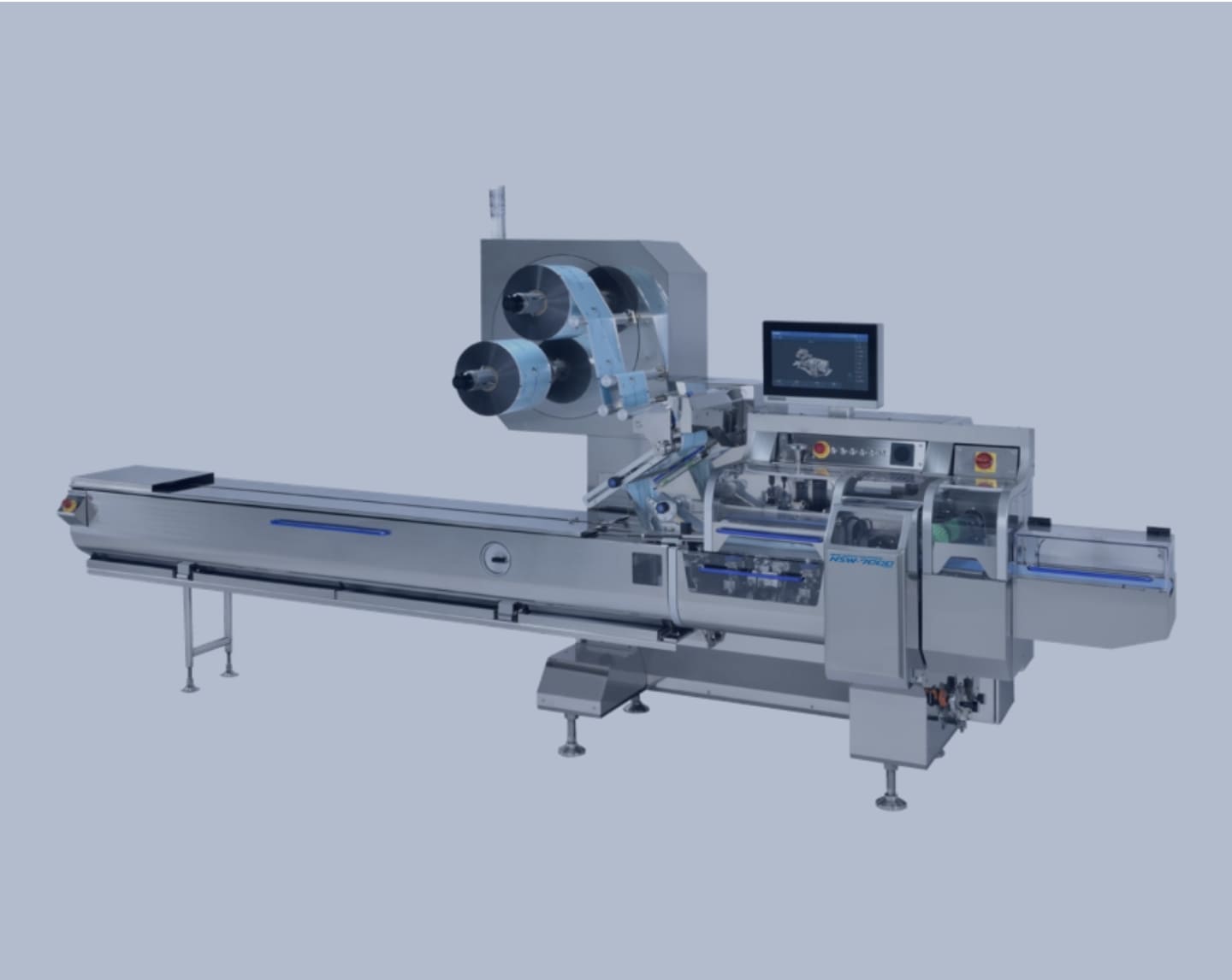

The NSW-7000: A New Automatic Horizontal Form-Fill-Seal Machine Created in the Pursuit of Convenience

The NSW-7000 is a new type of automatic horizontal form-fill-seal machine built not to a manufacturer’s standards, but instead for usability and convenience from the user’s perspective. Since the project was formed in 2015, we have gathered information mainly from customer requests and reviewed each part of the machine. We released the first model at JapanPack2019.

STORY.2

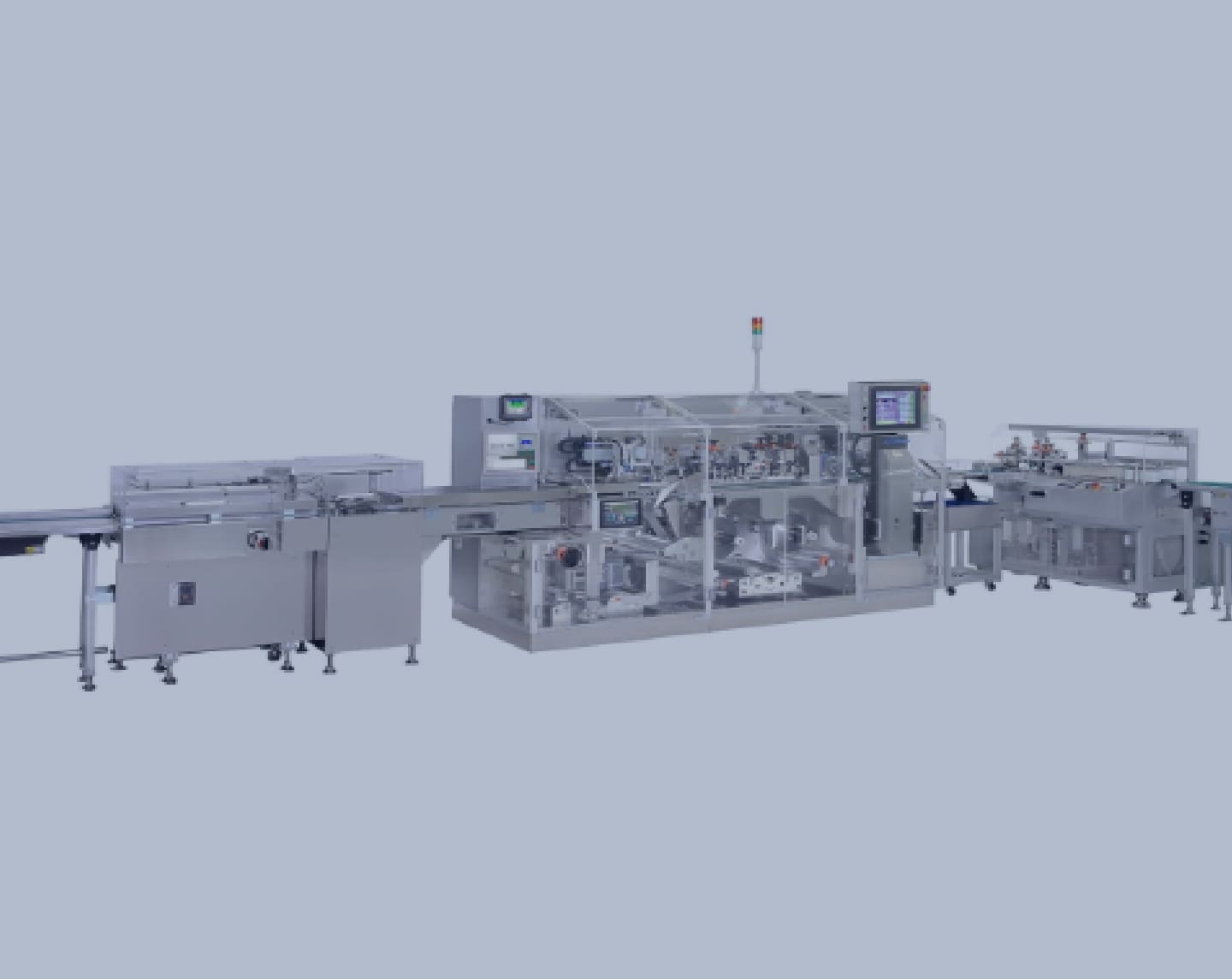

The S-7680: A high-speed automatic horizontal form-fill-seal machine for pharmaceutical products

S-7680

A decade has passed since the development of the first packaging machine specialized for pharmaceutical products.

We reviewed the basic design of the existing machine and found there was a need to develop a new machine. A new project team was put together and development of the S-7680 began. The entire team racked their brains to solve each problem one by one, and completed the project after much trial and error. Even now, follow-up work continues to address the rapidly changing production environment for pharmaceuticals.