Packaging machines suitable for cosmetics

Introducing OMORI's horizontal form-fill-seal machines, shrink wrapping machines and cartoners suitable for packaging cosmetics.

Examples: bottles, tubes, paper (sheets), antiperspirants, etc.

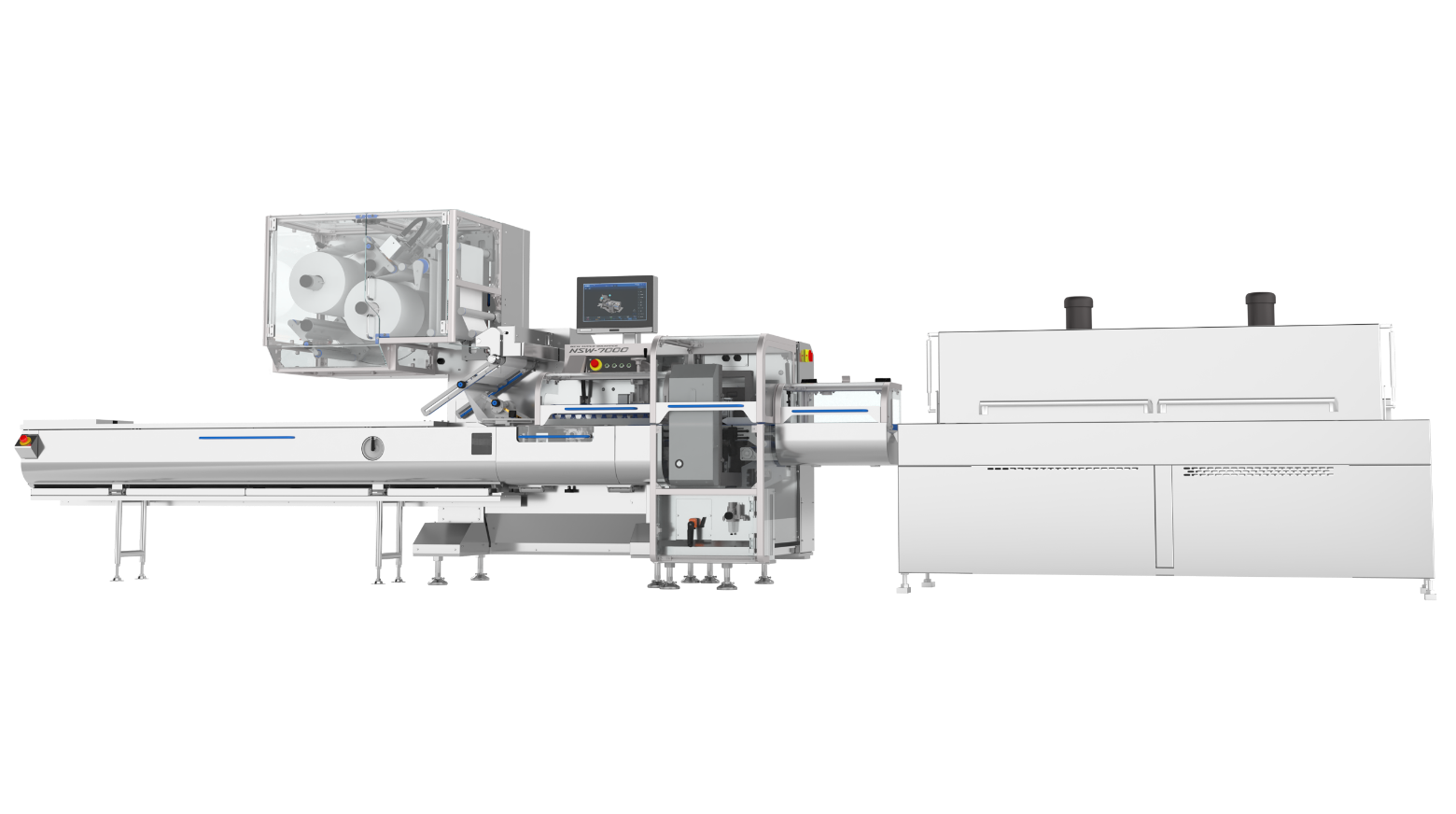

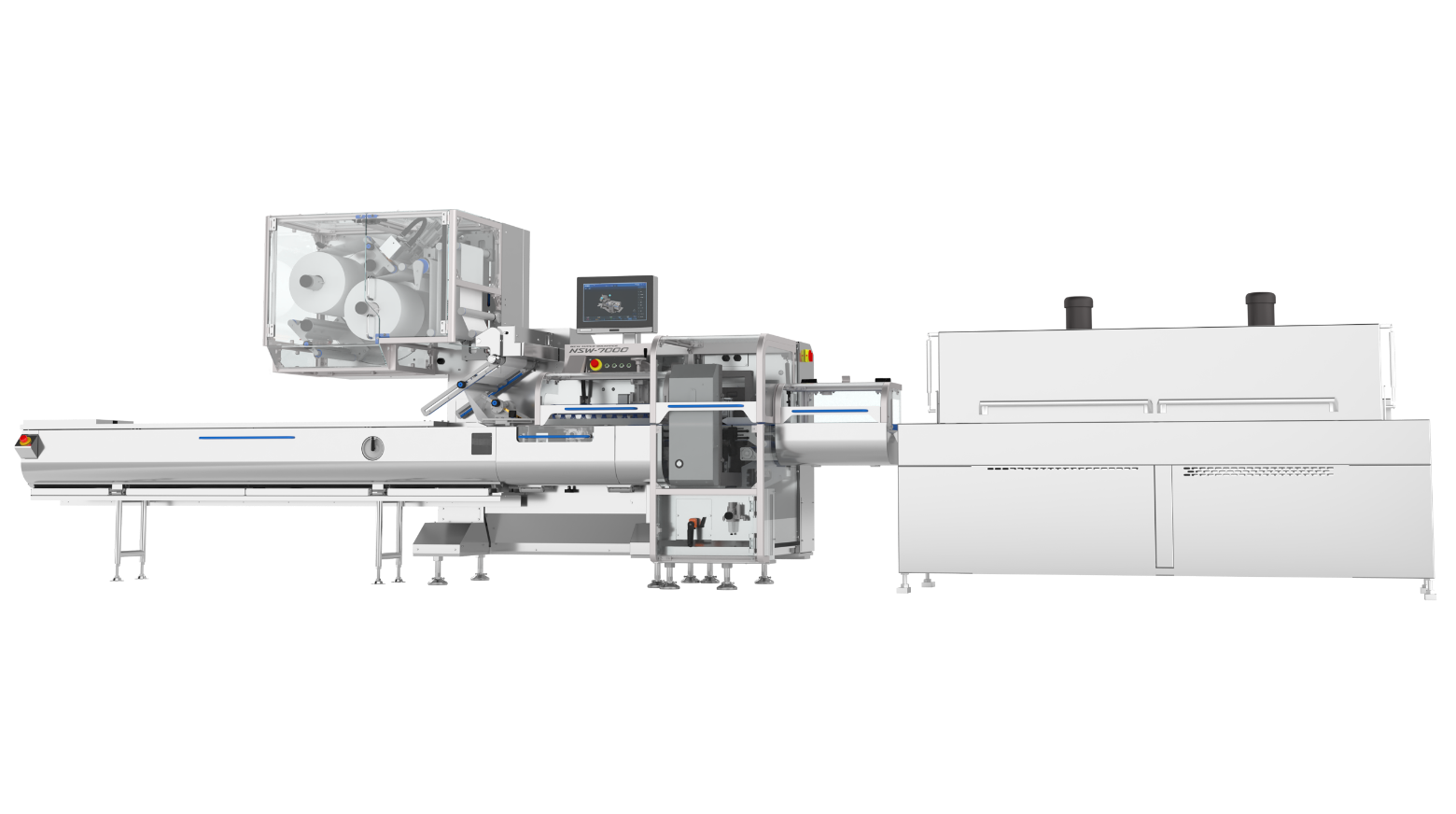

Horizontal Form-Fill-Seal Machines

- A new reverse pillow packaging machine for all industries, including food, cosmetics, and daily goods.

- The revolver type heat seal splicer makes film joining prep quick and easy. Conveyor workability and cleanability have also improved.

- Modular design makes unit-by-unit attachment/detachment and maintenance easy.

- The UI screen uses 3D models and icons for intuitive operation.

DETAIL

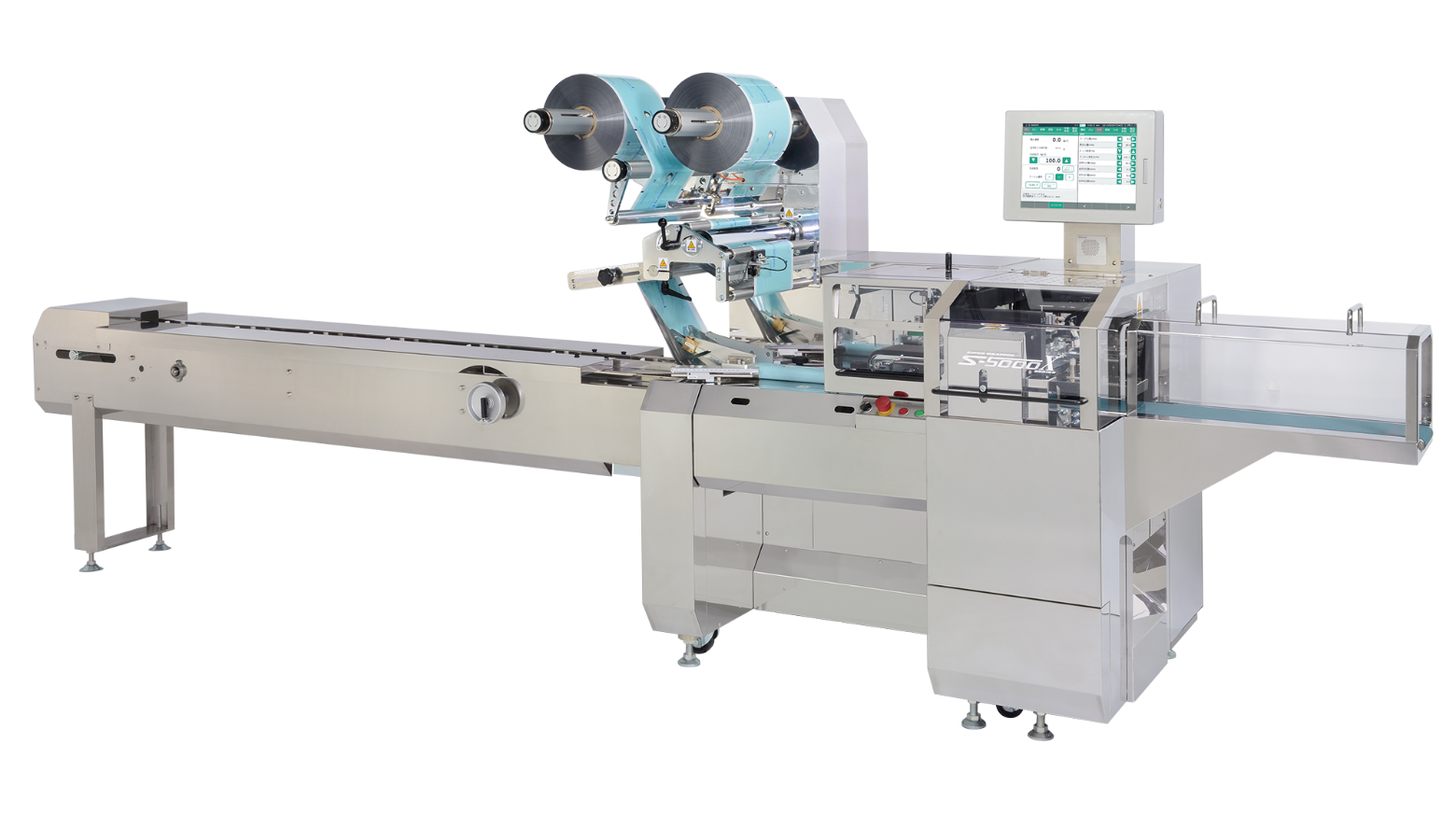

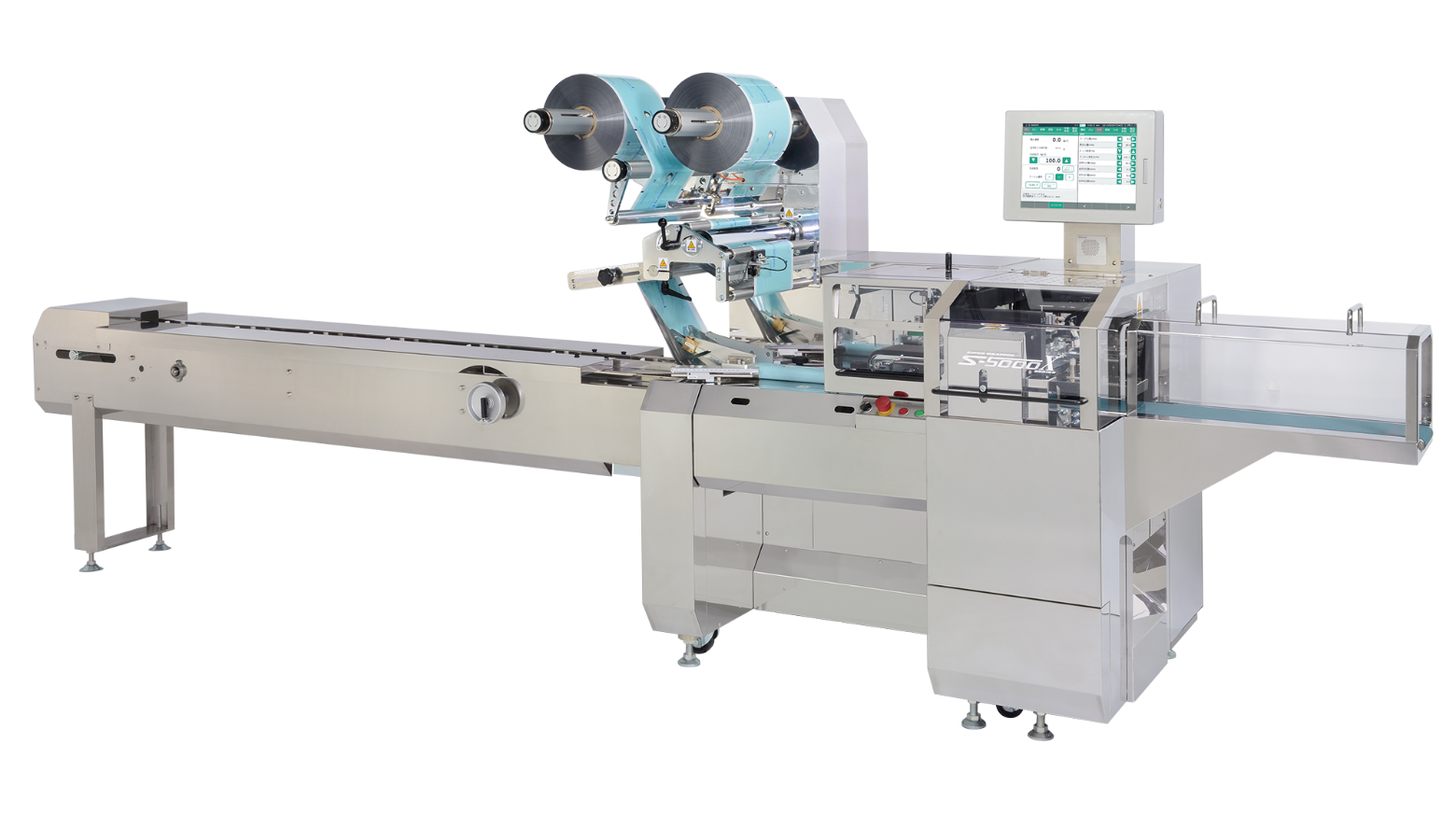

Horizontal Form-Fill-Seal Machines

- A new horizontal form fill shrink wrapping machine for all industries, including food, cosmetics, and daily goods.

- The revolver type heat seal splicer makes film joining prep quick and easy.

- Modular design makes unit-by-unit attachment/detachment and maintenance easy.

- Stable film feed control realizes outstanding finish even for full color shrink film.

- Two selectable end sealing types: rotary or box motion.

- Various center seal patterns, fin seal, weld seal,static seal and etc.are available upon request.

- The UI screen uses 3D models and icons for intuitive operation.

DETAIL

Horizontal Form-Fill-Seal Machines

- A standard horizontal form-fill-seal machine suitable for all industries, including food, cosmetics, and daily goods.

- Easy-to-use with large 15-inch display with dual screen display capability.

- Standard-equipped stainless steel cover for improved hygiene.

- Robust and sturdy construction for stable film feeding and sealing.

DETAIL

Horizontal Form-Fill-Seal Machines

- A standard reverse pillow packaging machine for all industries, including food, cosmetics, and daily goods.

- Can package multiple loose products without a tray and stick-shaped products.

- Can also handle confectionery, noodle, and coffee multi-packs, and soft product packaging.

- Having center sealing device on the upper surface makes it suitable for heat-sensitive products.

DETAIL

Horizontal Form-Fill-Seal Machines

- A standard fingerless horizontal form fill shrink wrapping machine for all industries, including food, cosmetics, and daily goods.

- Stable film feed control realizes outstanding finish, even for full color shrink film.

- Two selectable end sealing types: rotary or box motion.

- Various center seal patterns, fin seal, weld seal,static seal and etc.are available upon request.

DETAIL

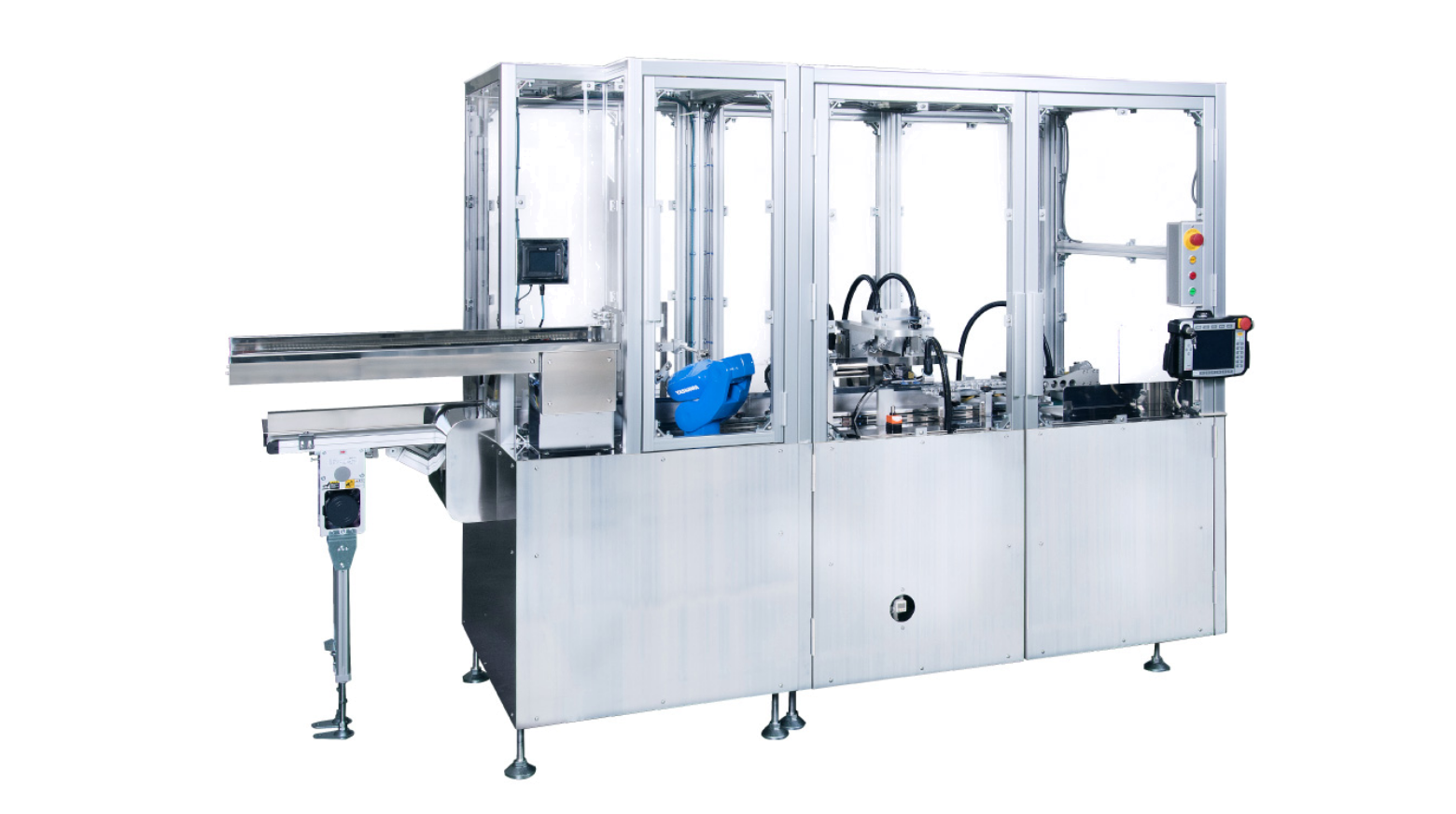

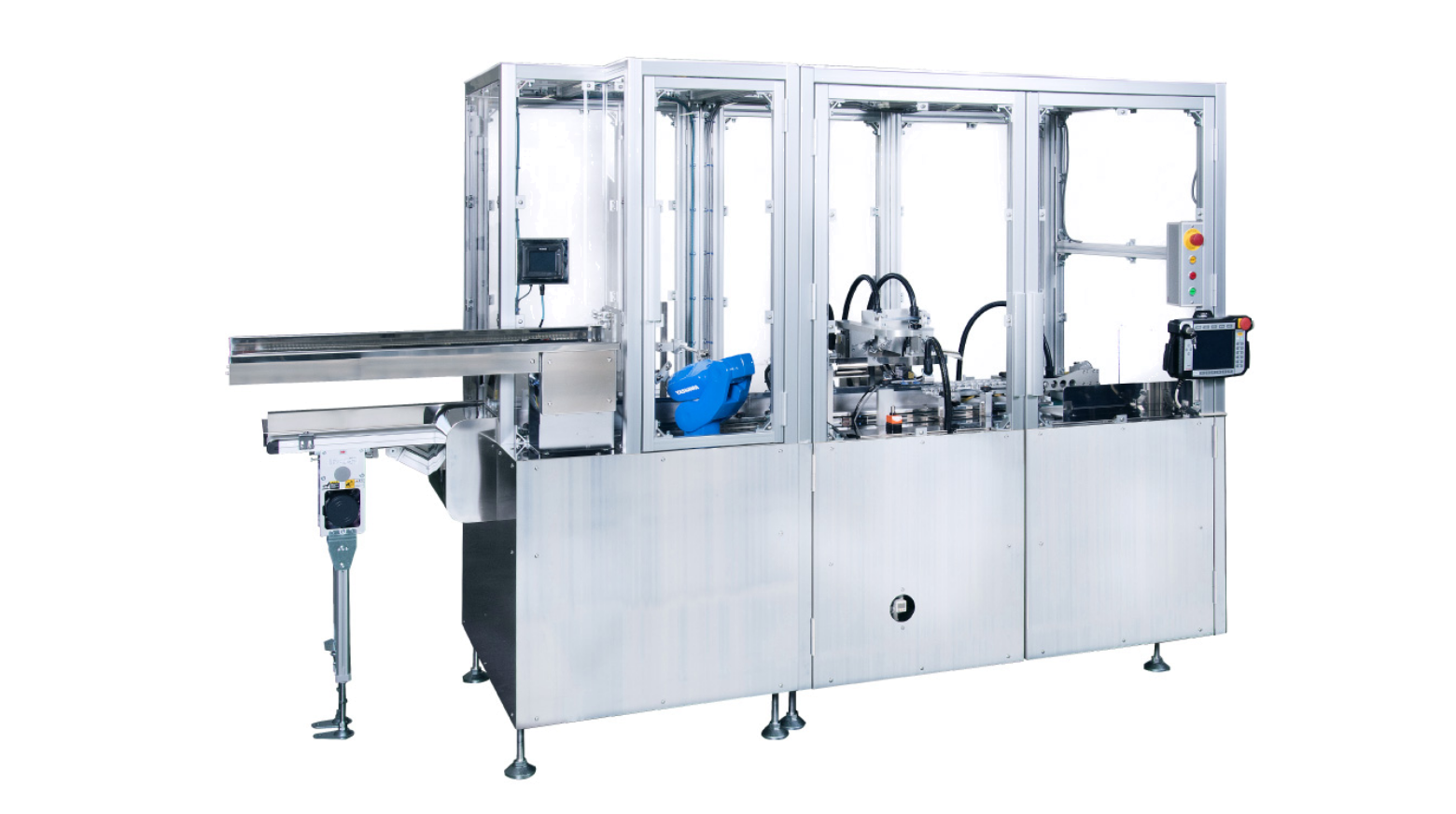

Cartoners

- A cartoner that removes one-touch cartons from the stocker, automatically locks the bottom, and uses robot hand or other means to automatically supply the collected products.

- Cartoning machine for PTP 50-sheet and 100-sheet band products and pillow products.

- Suitable for automation of a wide variety of products that were previously manually packed in one-touch boxes.

- Over-flap gluing and insertion tape can also be used for closing.

- Various types of automatic document feeders and inspection devices can be accommodated within the machine.

DETAIL

Cartoners

- A gluing and sealing machine that can handle one-touch boxes.

- After product is fed, it folds minor flaps and cover panel, and hot-melt seals the box.

- Compact with a length from box receipt to box sealing of 1 meter.

- Has a built-in positioning device to prevent misalignment and realize beautifully sealed cartons.

- Cartons adhere during crimping to ensure reliable sealing.

- The unit structure makes expansion to printers and other equipment easy.

DETAIL

Cartoners

- A new gluing and sealing machine with robot control.

- Receives product-filled bottom-sealed cartons and supplies package inserts using a small robot.

DETAIL

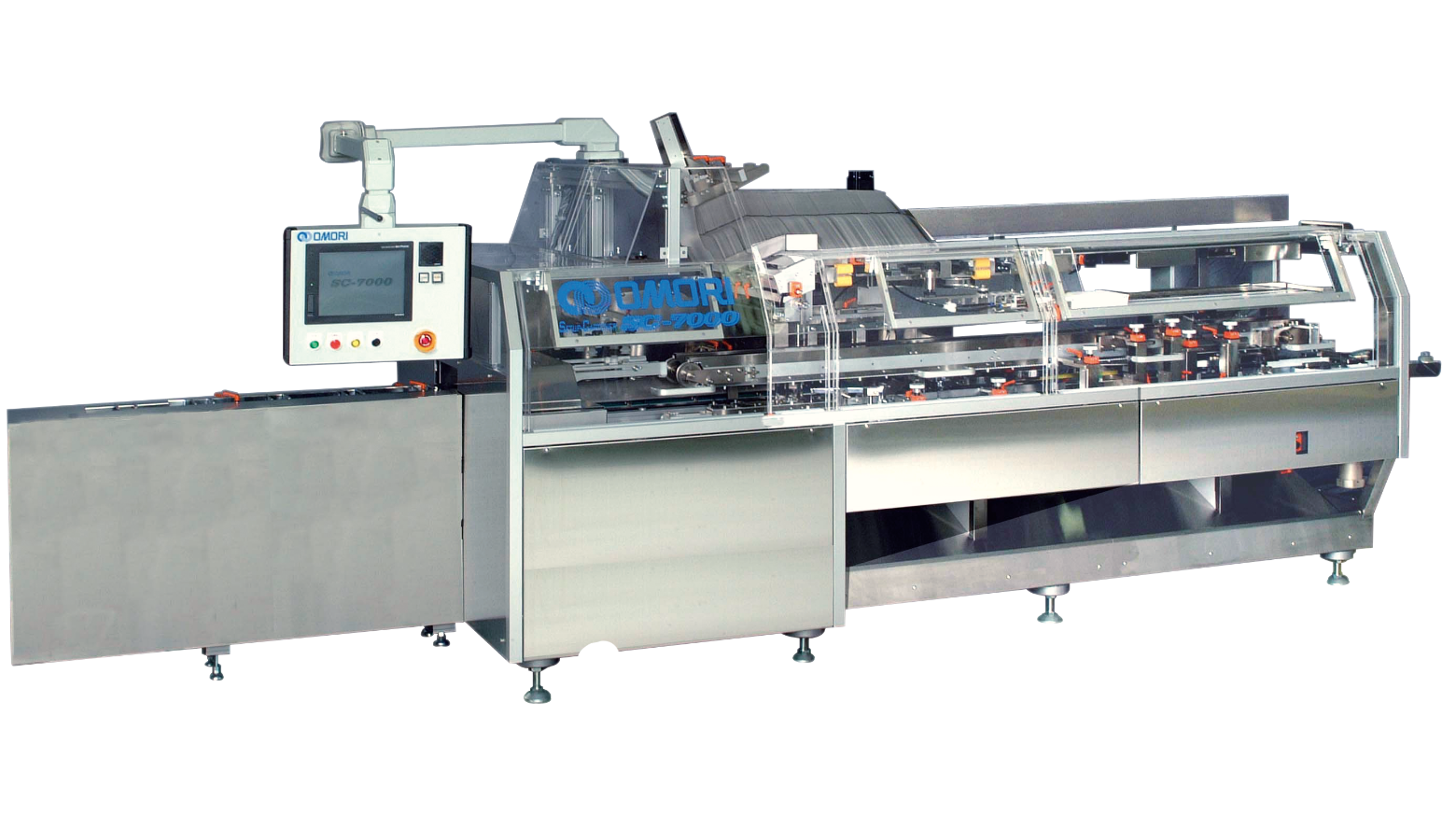

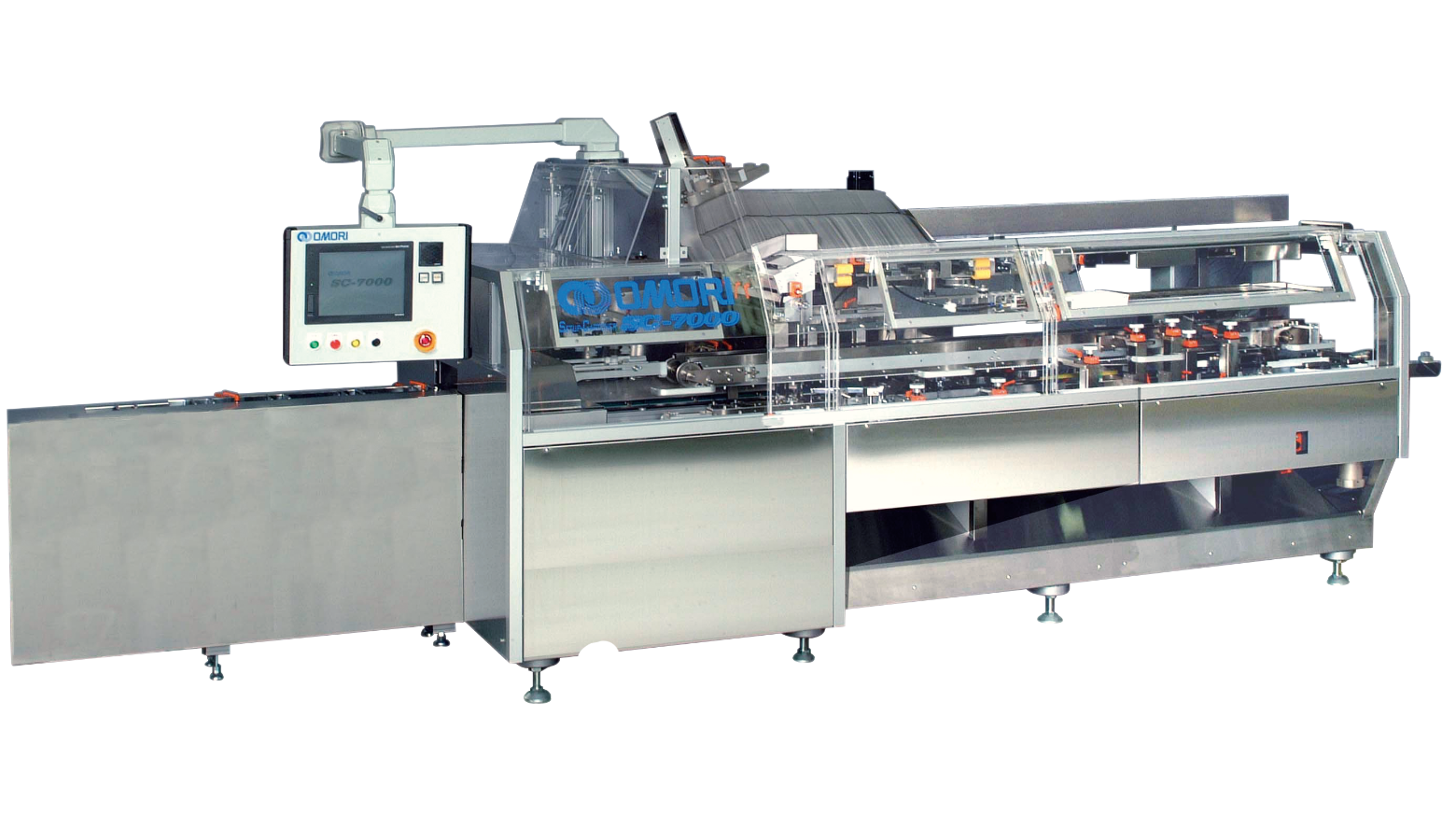

Cartoners

- Intermittent cartoner capable of packing 100, 500, or 1,000 tablets at the same time.

- Equipped with a timing belt attachment system for clean and deformation-free carton conveyance. (Lubrication-free, silent conveyance)

- Meets GMP guidelines through placement of drive unit on the back and the use of balcony-type conveyance.

- Can handle various flap shapes (3-flap, 4-flap, over-flaps).

- The carton hopper and document hopper located at the top of the machine slide as one to the rear for easy mold changeover and maintenance.

DETAIL

Cartoners

- A compact intermittent cartoner that can handle a wide range of products and commodities such as pharmaceuticals, nutritional supplements, cosmetics, and non-pharmaceutical products.

- Realizes low power consumption and inexpensive maintenance cost by reducing the number of drives to one.

- Machine structure does not obstruct the operator's view, allowing visual observation of the operation in progress.

- Minimal part sizes contribute to faster size changeover.

DETAIL

Horizontal Form-Fill-Seal Machines

Products

As professionals who handle the packaging process,

we offer the best packaging systems.