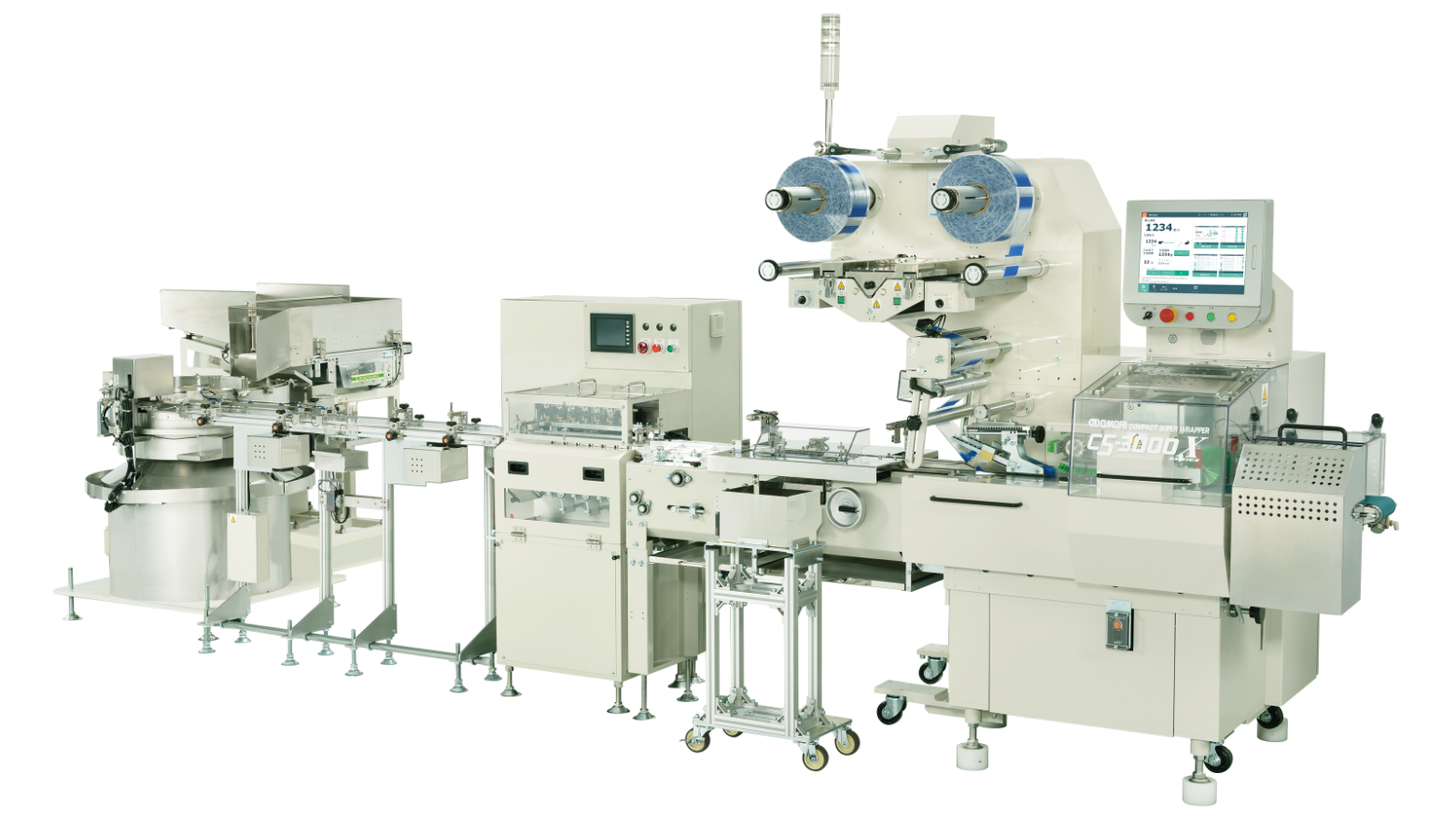

Packaging machines suitable for packaging Japanese and Western confectioneries

Introducing OMORI's horizontal form-fill-seal machines and cartoners suitable for packaging Japanese and Western confectioneries.

For example: rice crackers, dorayaki (bean jam pancakes), cookies, chocolates, steamed confections, etc.

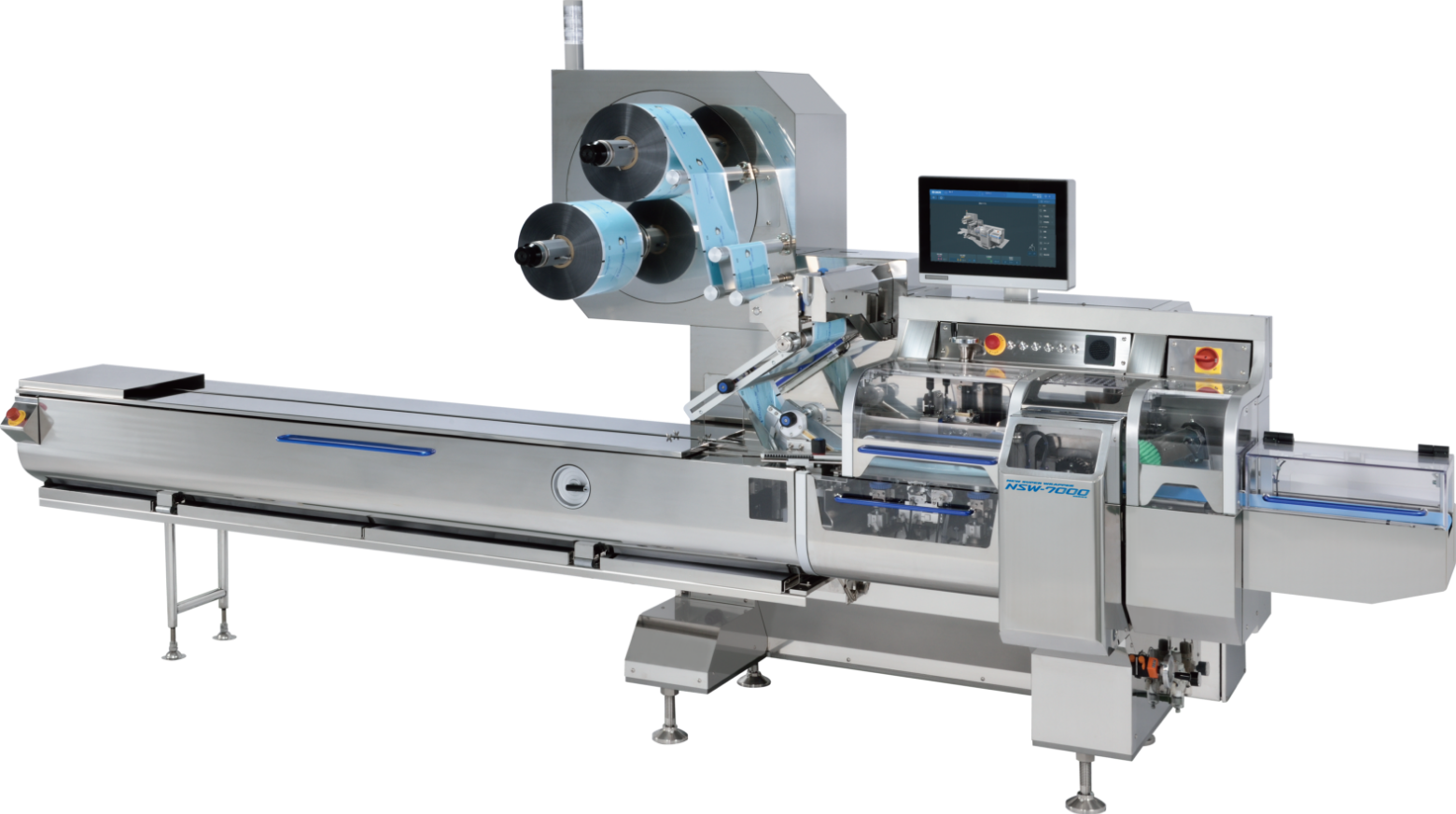

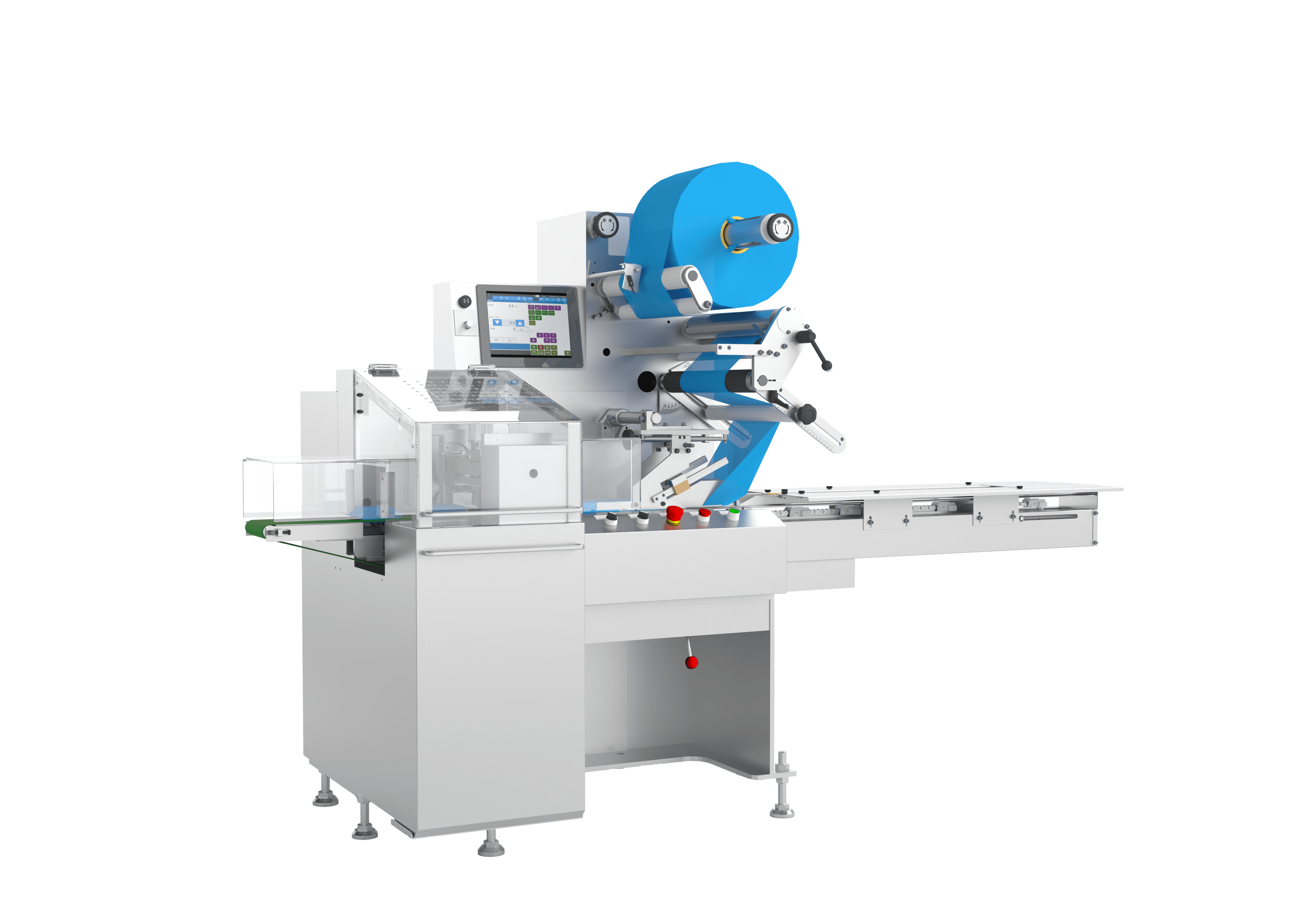

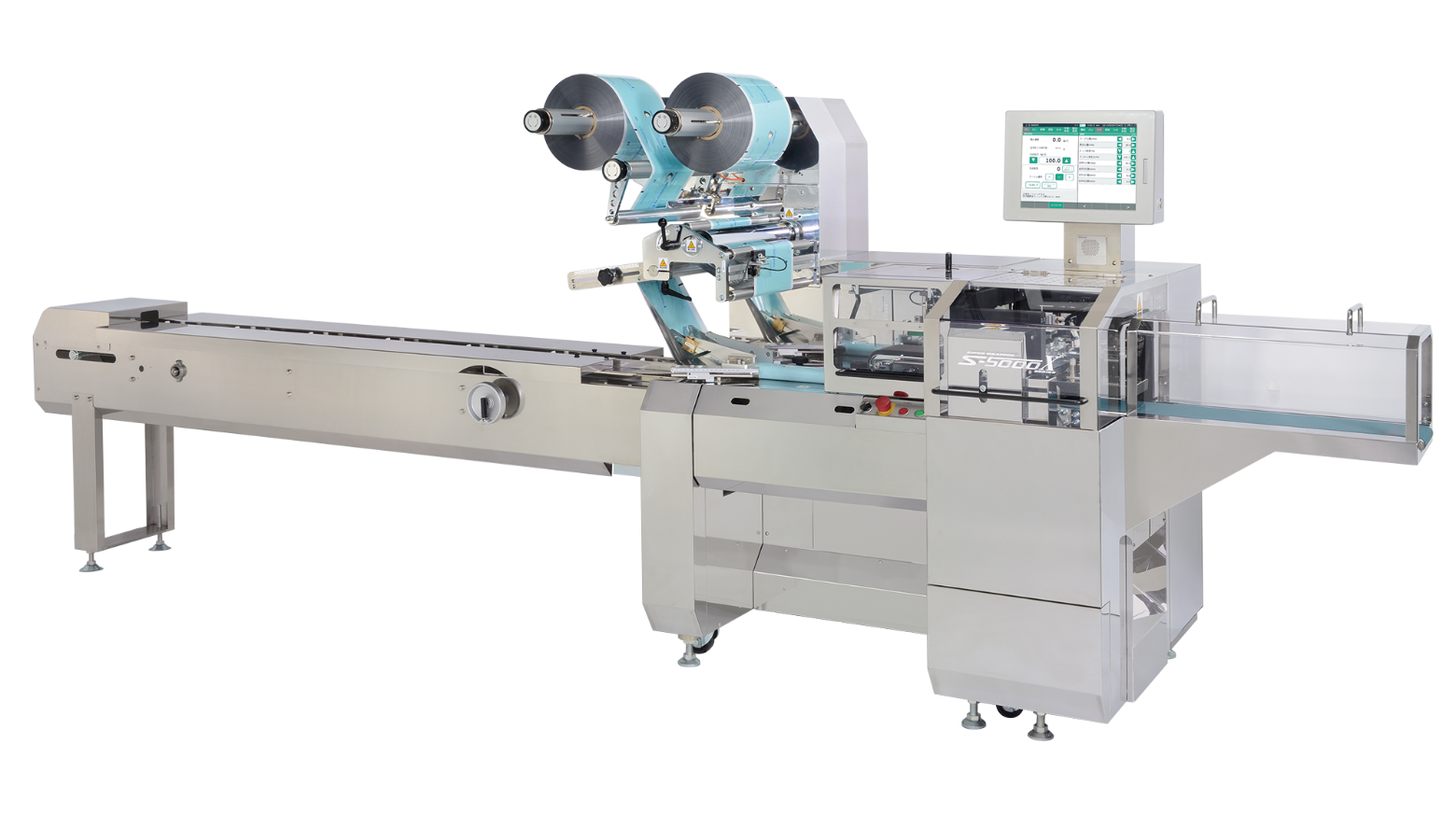

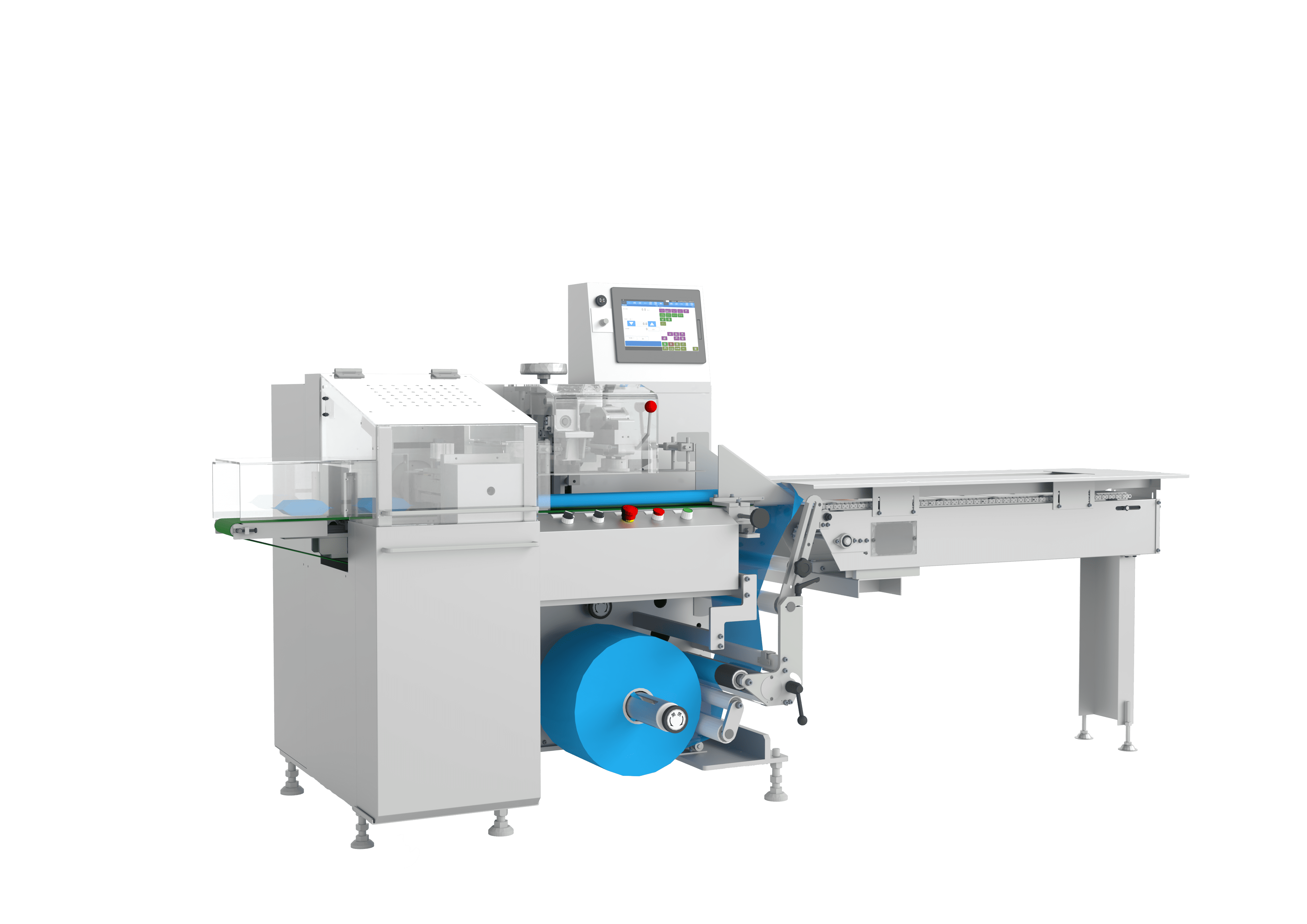

Horizontal Form-Fill-Seal Machines

- A new high-speed horizontal form-fill-seal machine for all industries, including food, cosmetics, and daily goods.

- Uses operator-friendly revolver type film supply with the film set in a low position.

- Using a frameless structure for the supply conveyor has improved tool-free attachment/detachment and finger chain cleanability.

- Modular design makes unit-by-unit attachment/detachment and maintenance easy. The upper plate and lower belt can also be opened and closed tools-free for easy cleaning.

- The UI screen uses 3D models and icons for intuitive operation.

DETAIL

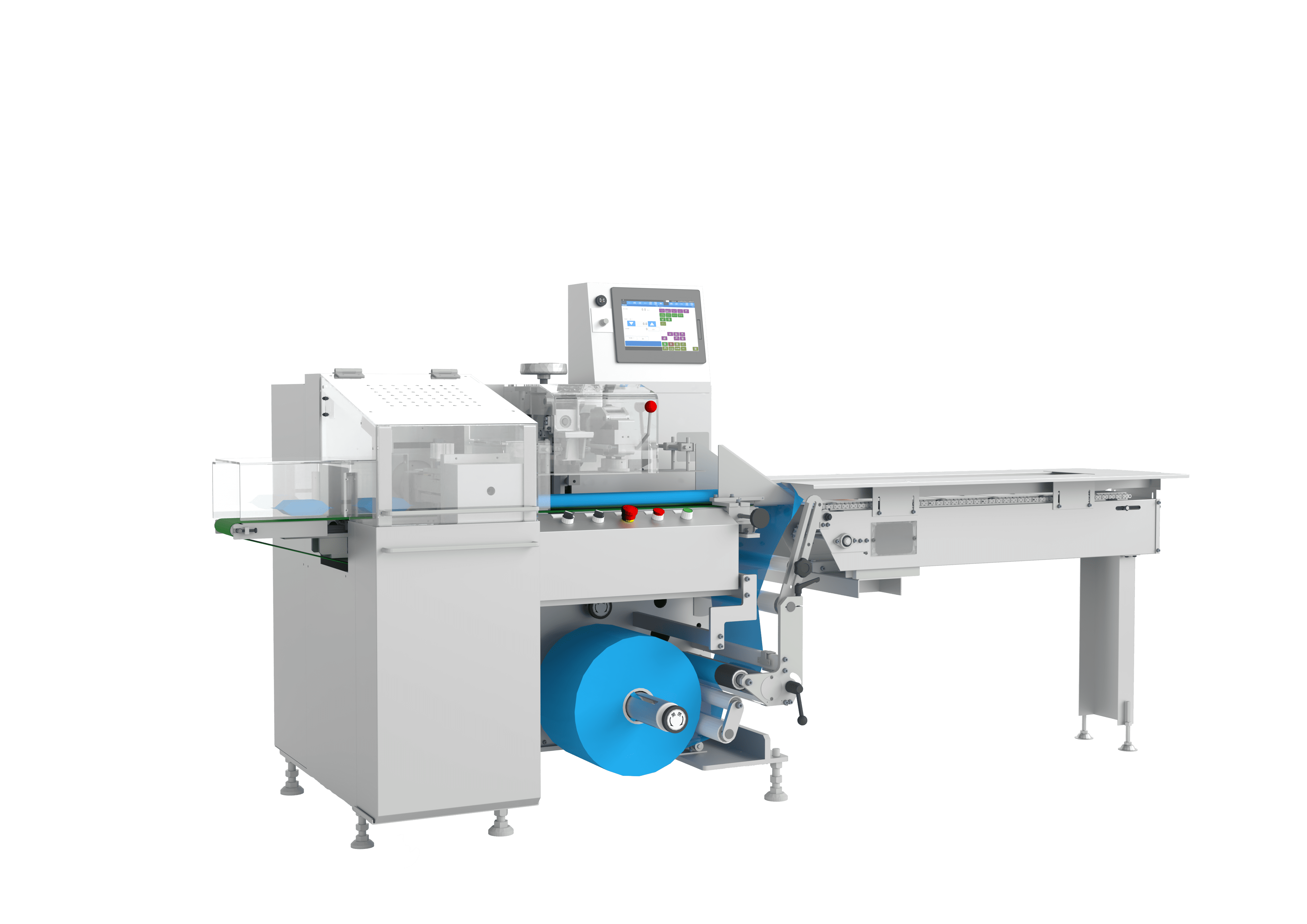

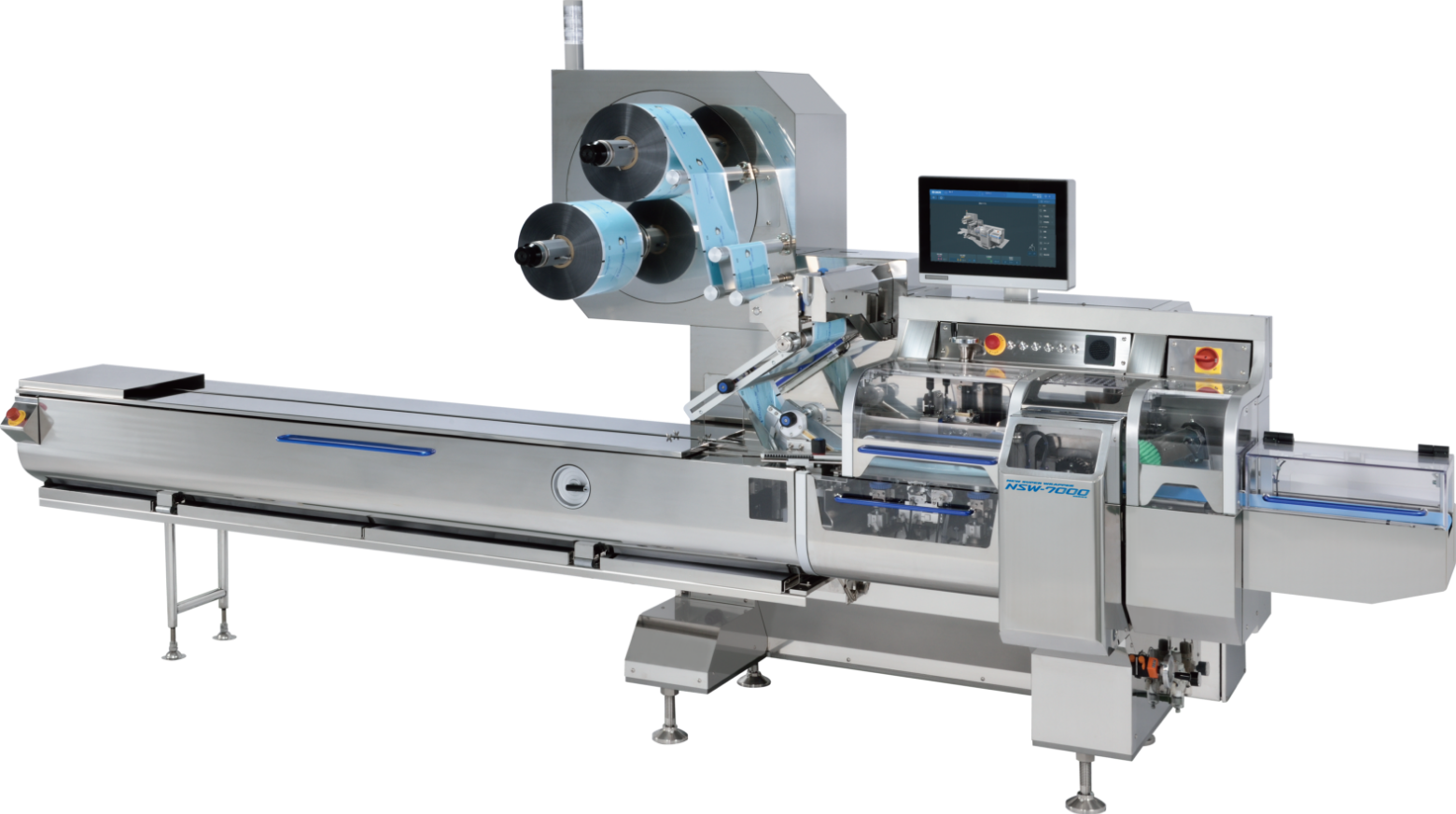

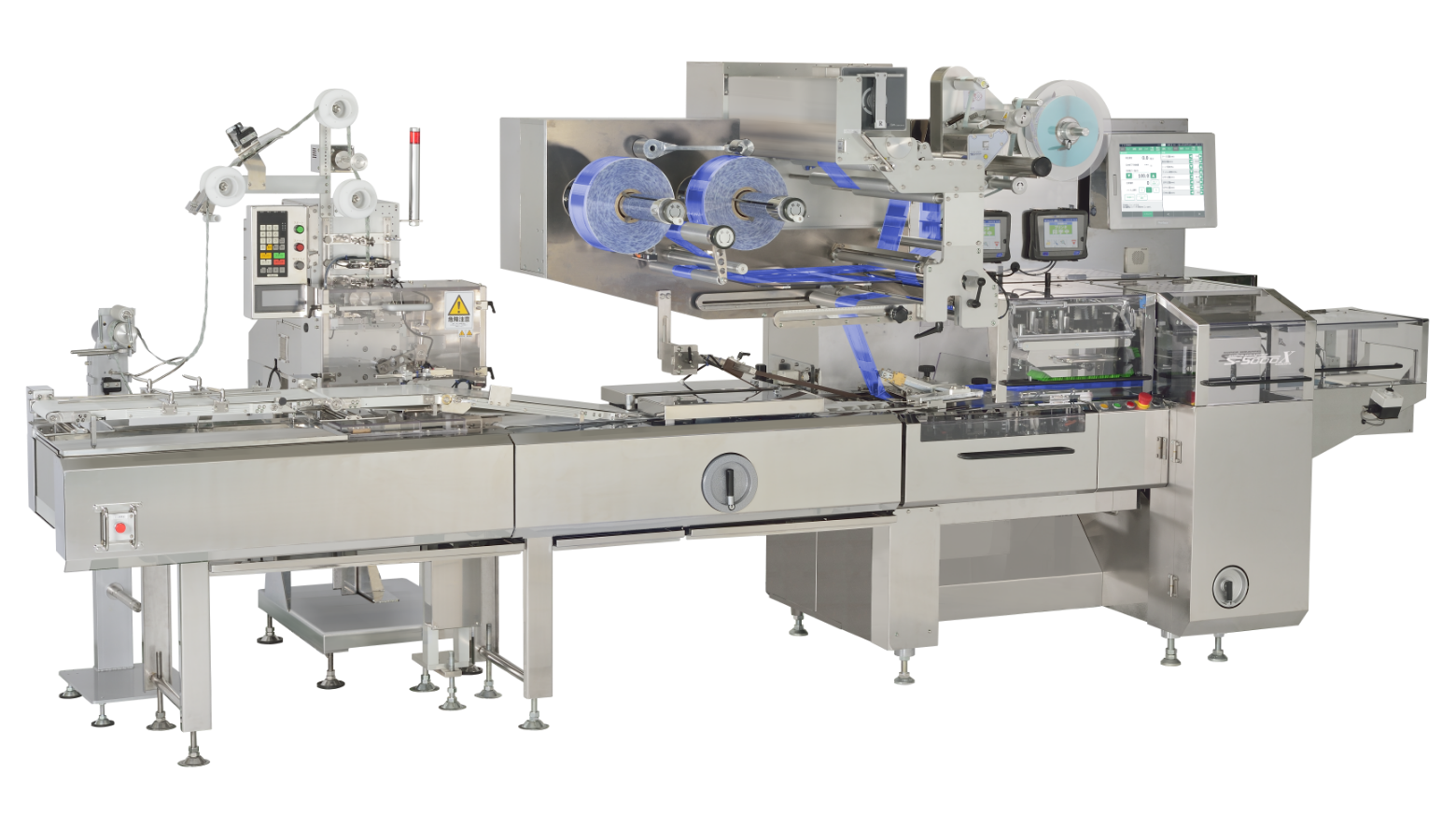

Horizontal Form-Fill-Seal Machines

- A new reverse pillow packaging machine for all industries, including food, cosmetics, and daily goods.

- The revolver type heat seal splicer makes film joining prep quick and easy. Conveyor workability and cleanability have also improved.

- Modular design makes unit-by-unit attachment/detachment and maintenance easy.

- The UI screen uses 3D models and icons for intuitive operation.

DETAIL

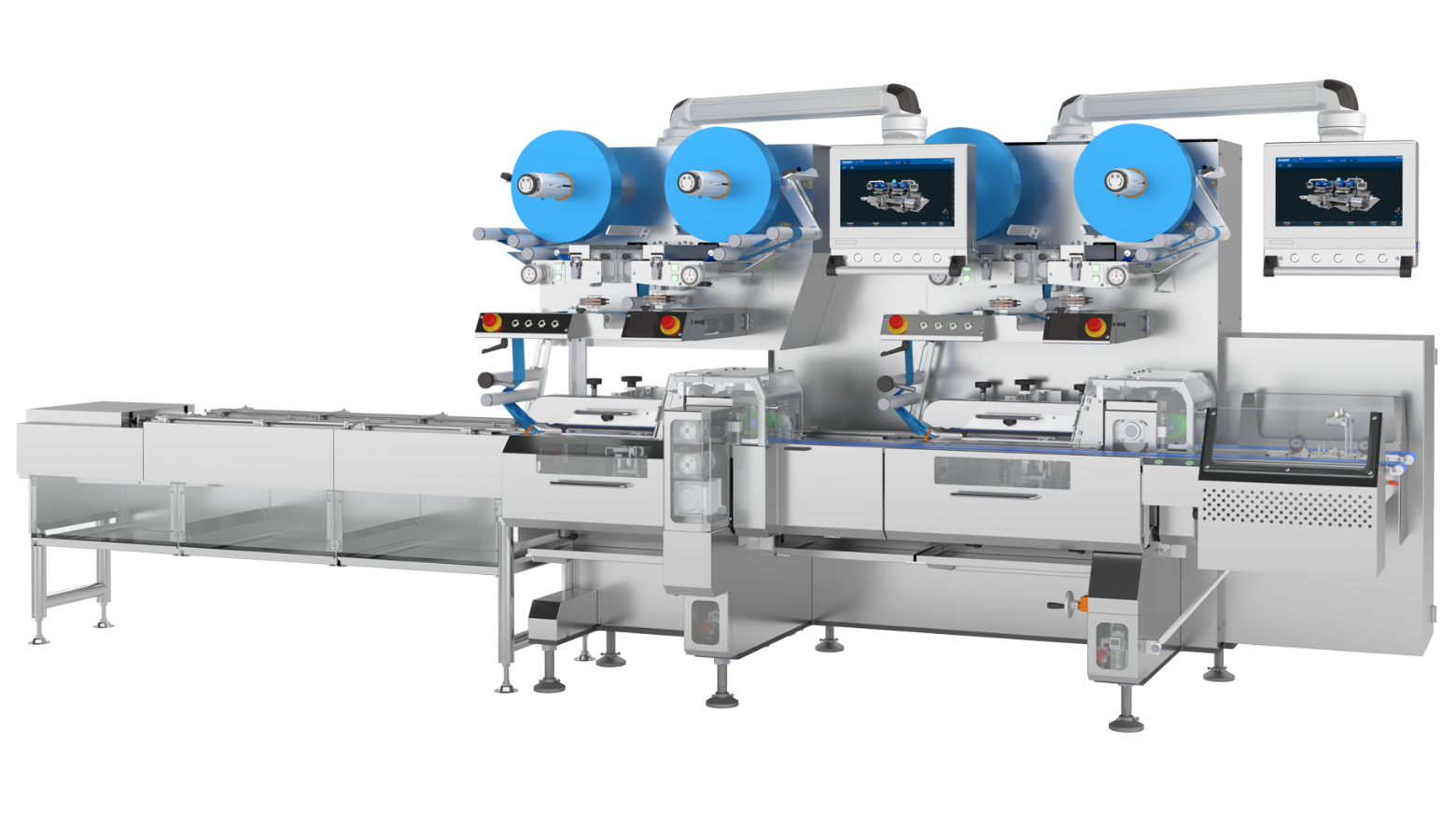

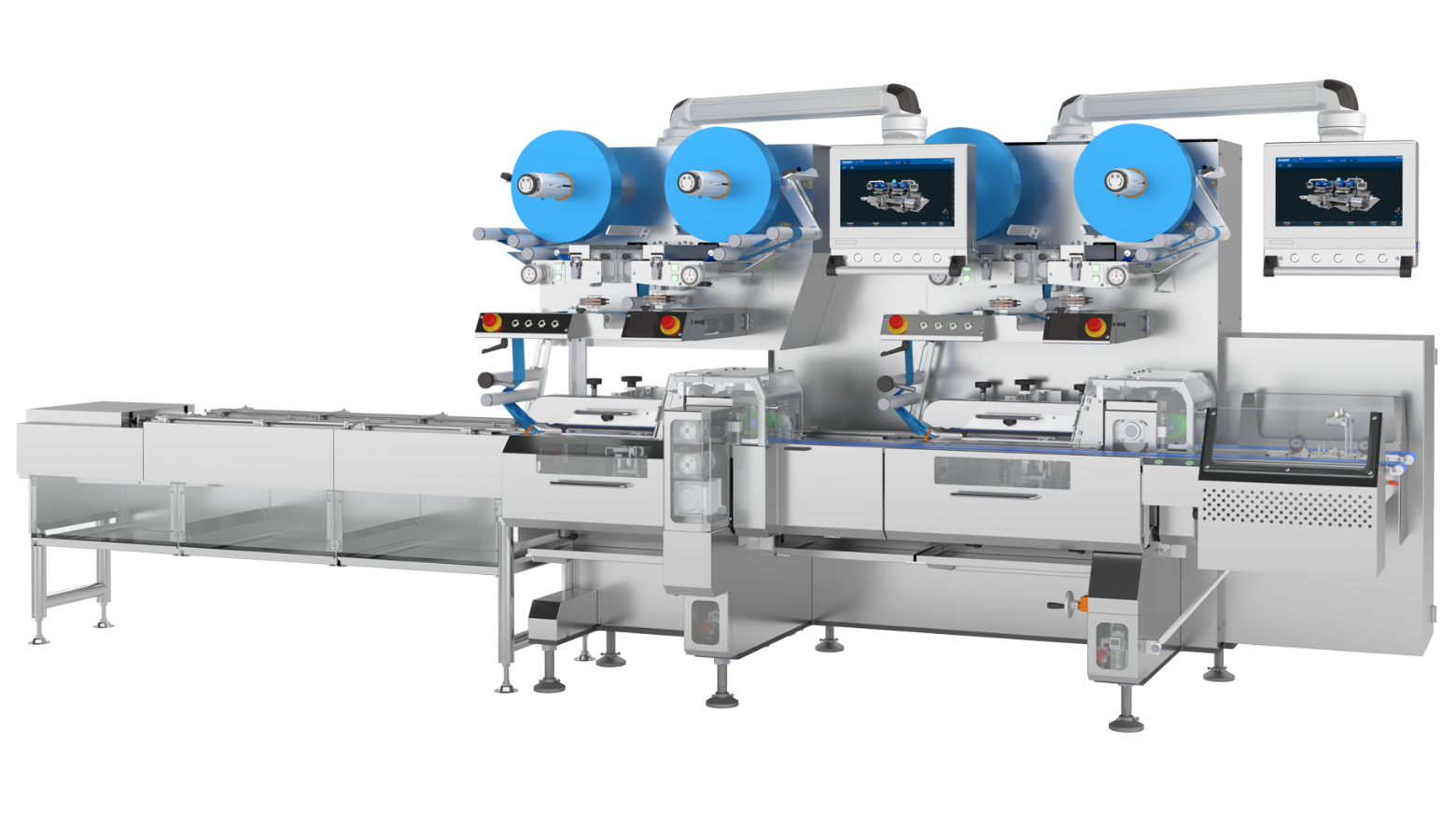

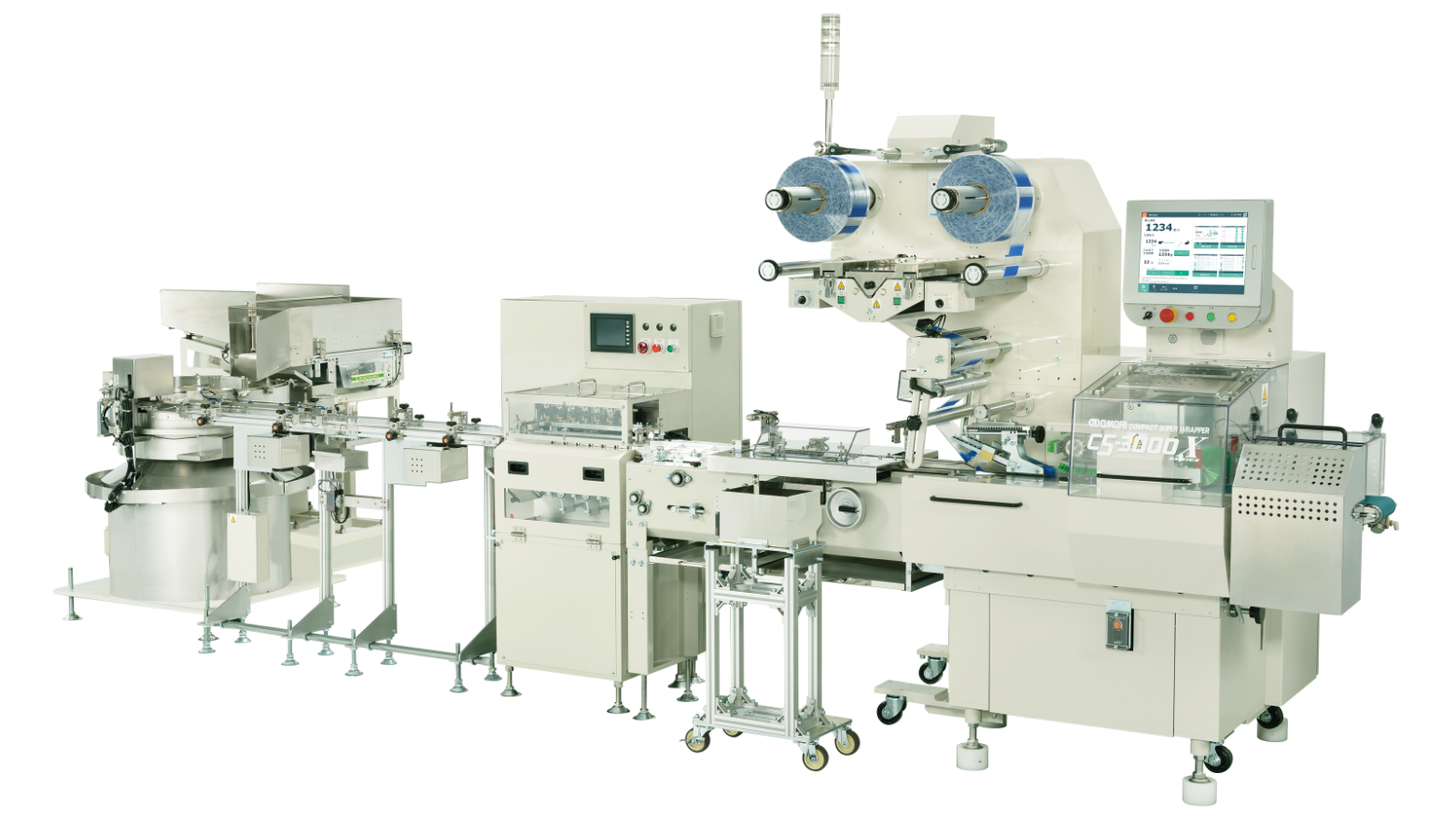

Horizontal Form-Fill-Seal Machines

- A new high-speed twin lane packaging machine for all industries, including food, cosmetics, and daily goods.

- Provides two functions in one and increased capacity. Saves space and manpower.

- Modular design makes unit-by-unit attachment/detachment and maintenance easy.

- The film supply section's standard-equipped raw material dancer control enables stable film feeding.

- The UI screen uses 3D models and icons for intuitive operation.

DETAIL

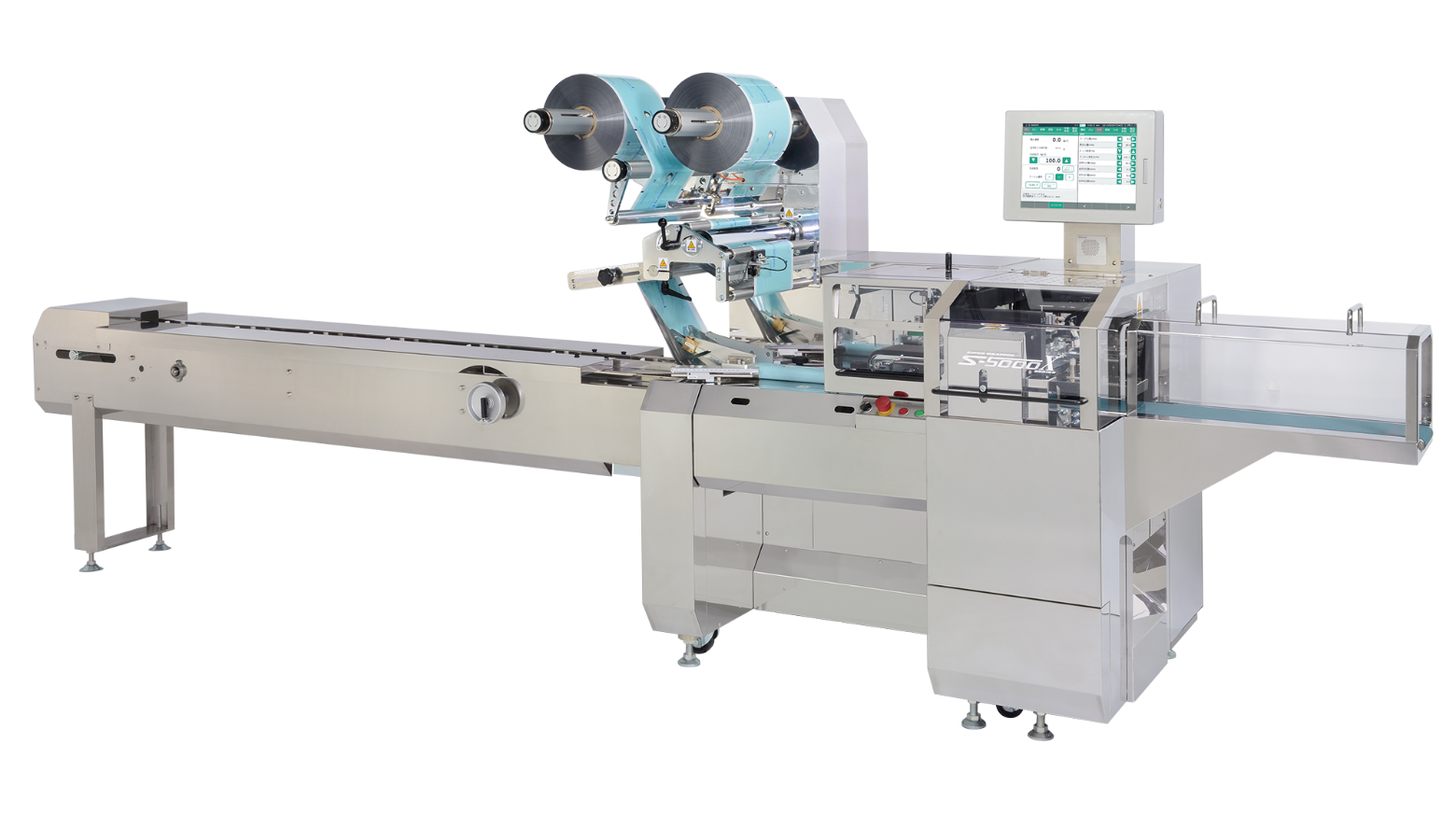

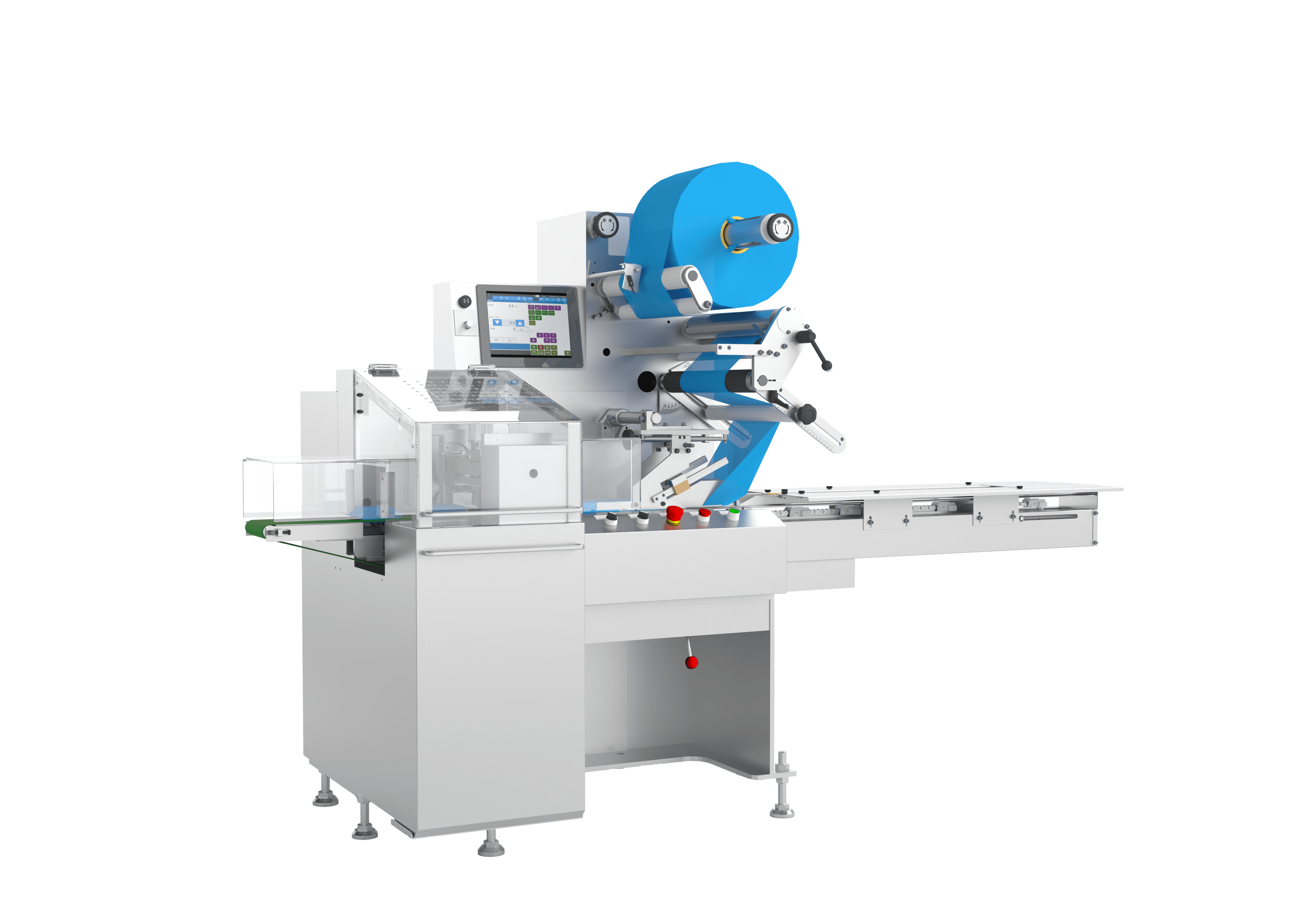

Horizontal Form-Fill-Seal Machines

- A standard horizontal form-fill-seal machine suitable for all industries, including food, cosmetics, and daily goods.

- Easy-to-use with large 15-inch display with dual screen display capability.

- Standard-equipped stainless steel cover for improved hygiene.

- Robust and sturdy construction for stable film feeding and sealing.

DETAIL

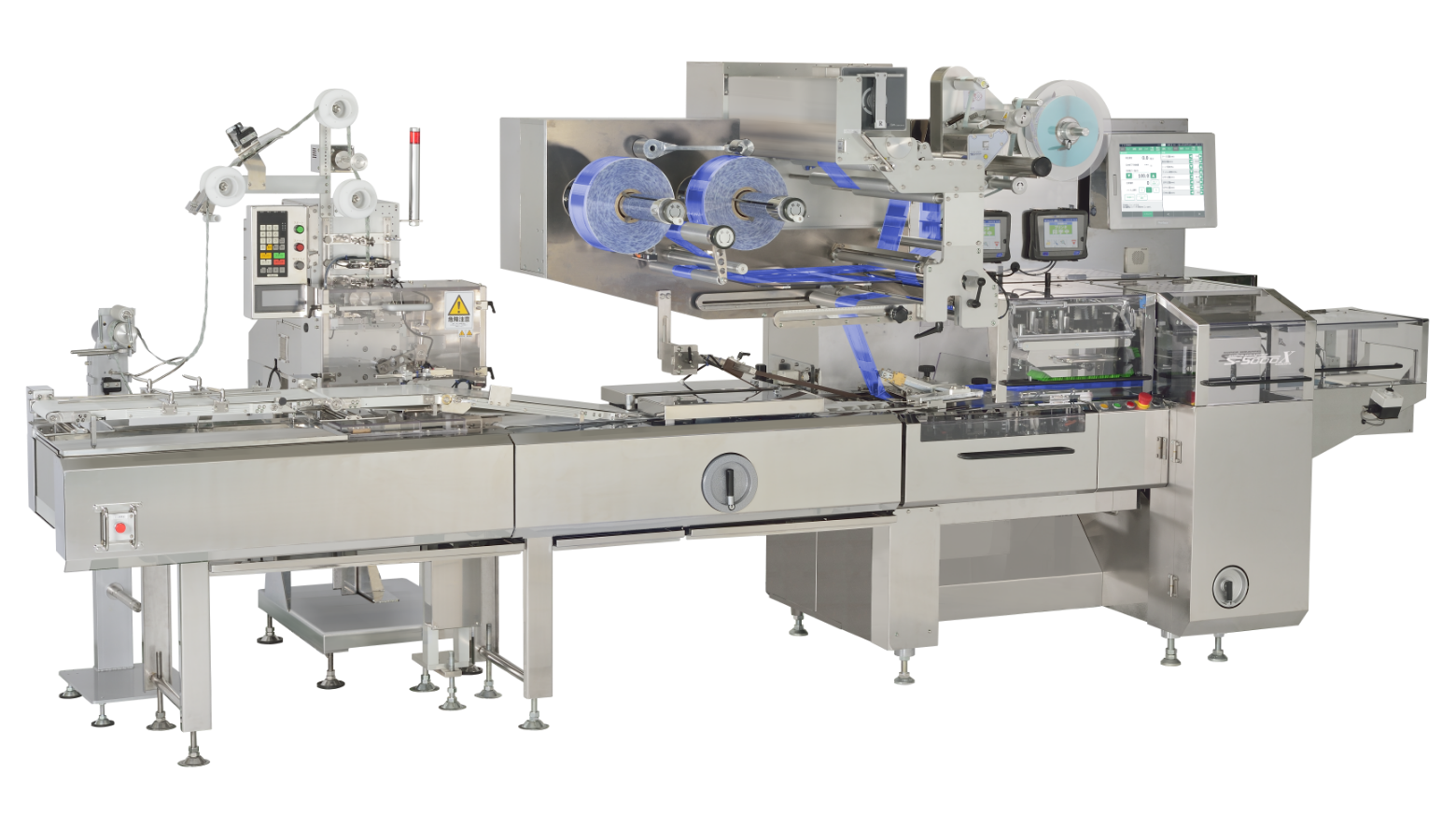

Horizontal Form-Fill-Seal Machines

- A standard reverse pillow packaging machine for all industries, including food, cosmetics, and daily goods.

- Can package multiple loose products without a tray and stick-shaped products.

- Can also handle confectionery, noodle, and coffee multi-packs, and soft product packaging.

- Having center sealing device on the upper surface makes it suitable for heat-sensitive products.

DETAIL

Horizontal Form-Fill-Seal Machines

- A standard fingerless horizontal form-fill-seal machine for all industries, including food, cosmetics, and daily goods.

- Advanced film tension control system enables stable feeding of thin, stretchy film.

- Belt in-feed conveyor is tool-free detachable, and completely detachable down to the frame for cleaning.

- Standard-equipped dump-type rejector prevents defective products from passing through to subsequent processes.

DETAIL

Horizontal Form-Fill-Seal Machines

- A standard fingerless horizontal form-fill-seal machine for all industries, including food, cosmetics, and daily goods.

- Belt in-feed conveyor feeds delicate products gently.

- Standard-equipped automatic feeder can receive products directly from the previous process (manufacturing machine).

- Belt in-feed conveyor is tool-free and one-touch detachable for easy maintenance and cleaning.

DETAIL

Horizontal Form-Fill-Seal Machines

- A standard fingerless horizontal form-fill-seal machine for the food industry.

- With standard-equipped automatic feeder.

- Good for soft and delicate products.

- Edge-seal or fold line device may be added to enhance sense of product quality.

- Oxygen absorber (under the product) and gas filling realize longer product life.

DETAIL

Horizontal Form-Fill-Seal Machines

- A high-speed twin lane form-fill-seal machine suitable for all industries, including food, cosmetics, and daily goods.

- Provides two functions in one and increased capacity. Saves space and manpower.

- Easy-to-use with large 15-inch display with dual screen display capability.

- Standard-equipped stainless steel cover for improved hygiene.

- Robust and sturdy construction for stable film feeding and sealing.

DETAIL

Horizontal Form-Fill-Seal Machines

- A fingerless mid-size Inverted machine for all industries, including food, cosmetics, and daily goods.

- Inherits S-5000 series technology; compact body for effective use of space.

- Equipped with 5-axis servo control for stable packaging performance.

- Can receive products directly from the previous process (manufacturing machine).

- Uses conveyor belt infeed system.

DETAIL

Horizontal Form-Fill-Seal Machines

- A fingerless mid-size Inverted machine for all industries, including food, cosmetics, and daily goods.

- Inherits S-5000 series technology; compact body for effective use of space.

- Equipped with 5-axis servo control for stable packaging performance.

- Can receive products directly from the previous process (manufacturing machine).

- Uses conveyor belt infeed system.

DETAIL

Horizontal Form-Fill-Seal Machines

- A midle range, high-speed horizontal form-fill-seal machine for all industries, including food, cosmetics, and daily goods.

- Easy-to-use with large 15-inch display with dual screen display capability.

- Rotary-seal type end seal system enables high-speed packaging.

- Initial alignment at power-on and after trouble recovery now automated.

- Easy dual-use packaging.

DETAIL

Horizontal Form-Fill-Seal Machines

- Space-saving Midlle range Horizontal Form-Fill-Seal Machine

- With a touch panel for easy operation.

- Various product feeding methods can be selected according to the product item.

- Simple design for easy maintenance.

DETAIL

Horizontal Form-Fill-Seal Machines

- Space-saving Inverted Compact Horizontal Form-Fill-Seal machine for all industries, including food, cosmetics, and daily goods.

- With a touch panel for easy operation.

- Various product feeding methods can be selected according to the product item.

- Simple design for easy maintenance.

DETAIL

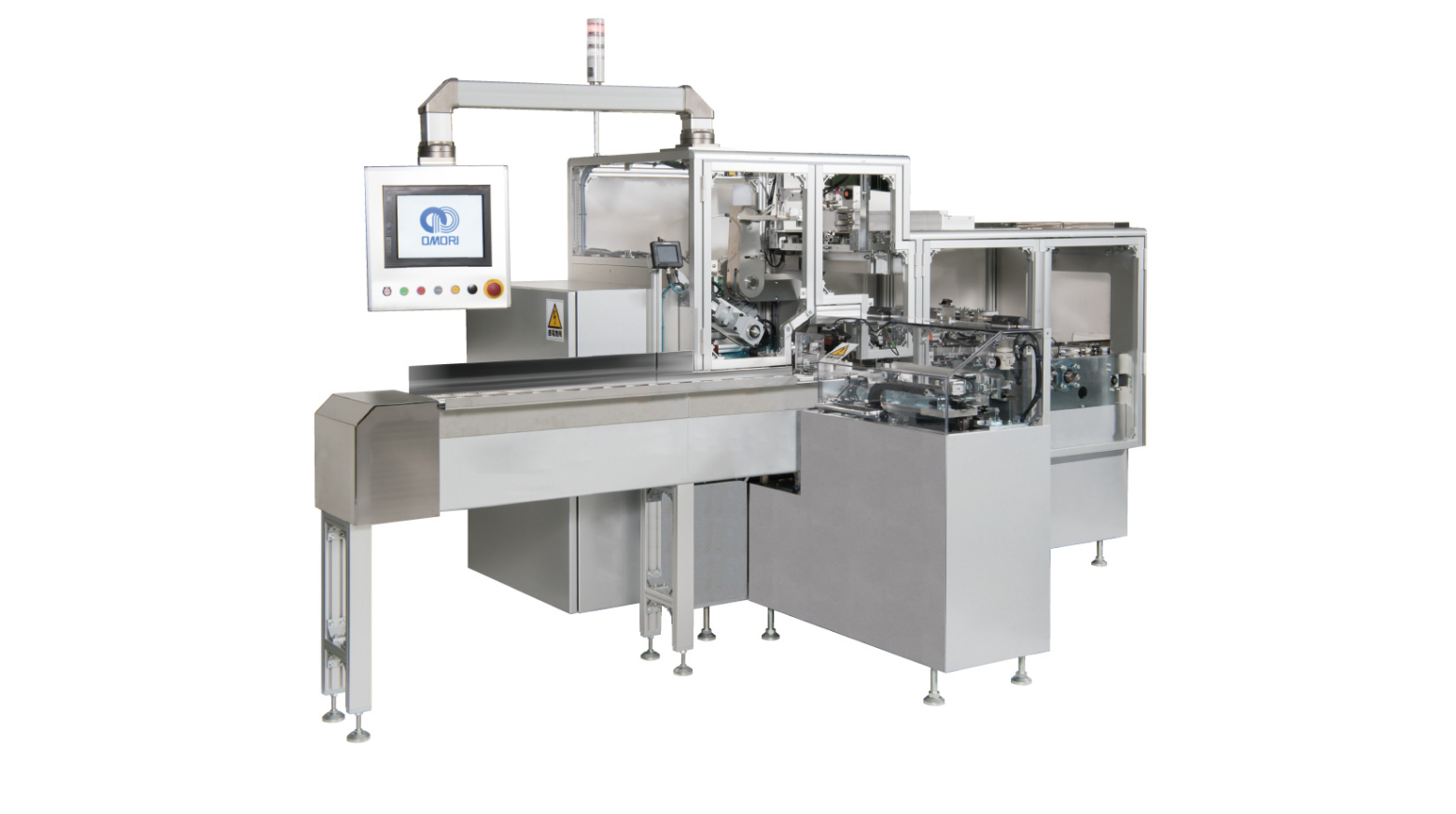

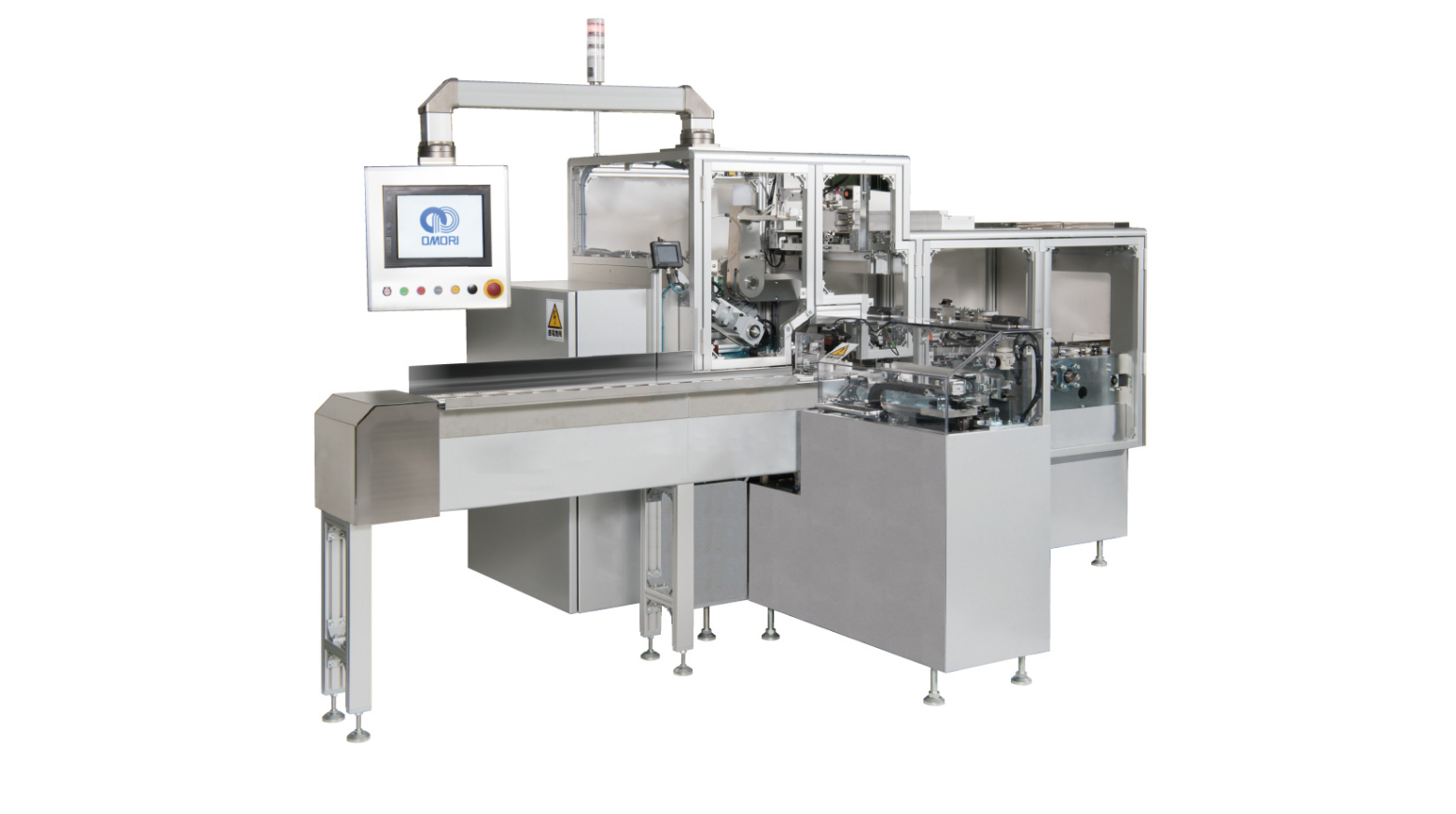

Cartoners

- A wraparound cartoner with a single blank sheet to achieve a tight finish.

- Suitable for packing thin products into boxes.

- Smoothly integrates with horizontal form-fill-seal machine and stretch wrapping machine in the front-end process, and medium box machine and caser in the back-end process, for enhanced line smoothness.

- A wide variety of carton styles are available, including 3-, 4-, and 5-flap cartons, 3-flap cartons with hooks, and inner carton configurations.

DETAIL

Cartoners

- An inner box wraparound cartoner that wraps onto a single blank sheet, resulting in a slim, beautiful, and tight finish.

- The opening method can be tweaked to great effect for product display.

- Can handle unstable multiple items.

- OMORI updated the drive system with a full servo system.

- The servo system makes it easier to handle a wide variety of products.

- Choice of various enhanced optional devices.

DETAIL

Cartoners

- A wraparound cartoner with a single blank sheet to achieve a tight finish.

- Has a standard-equipped color LCD screen.

- Conveys products on a flat surface, making it suitable for multiple products and collected products.

- Size change is by handle scale system, which provides restorability and easy operation.

- Allows installation of various enhanced optional devices.

DETAIL

Cartoners

- This compact intermittent end-load set-up cartoner feeds collected products into tubularly set cartons and performs molding and gluing.

- Can carton all kinds of products, and can also use corrugated cardboard, paperboard, plastic cartons, and other carton materials.

- Covers a wide range of low to medium speed products.

- A wide variety of collection devices are available to suit the product and collection configuration.

DETAIL

Cartoners

- Carton formers and closer formers capable of handling a wide variety of box formats, including tray, dust flap, and charlotte style.

- Absence of a single correct setting position facilitates line routing considerations.

- Mold replacement enables easy changing to different molds.

- Integrated line configuration enables connection to various feeding systems.

- Supply of accessories and incorporation of printing equipment also possible.

DETAIL

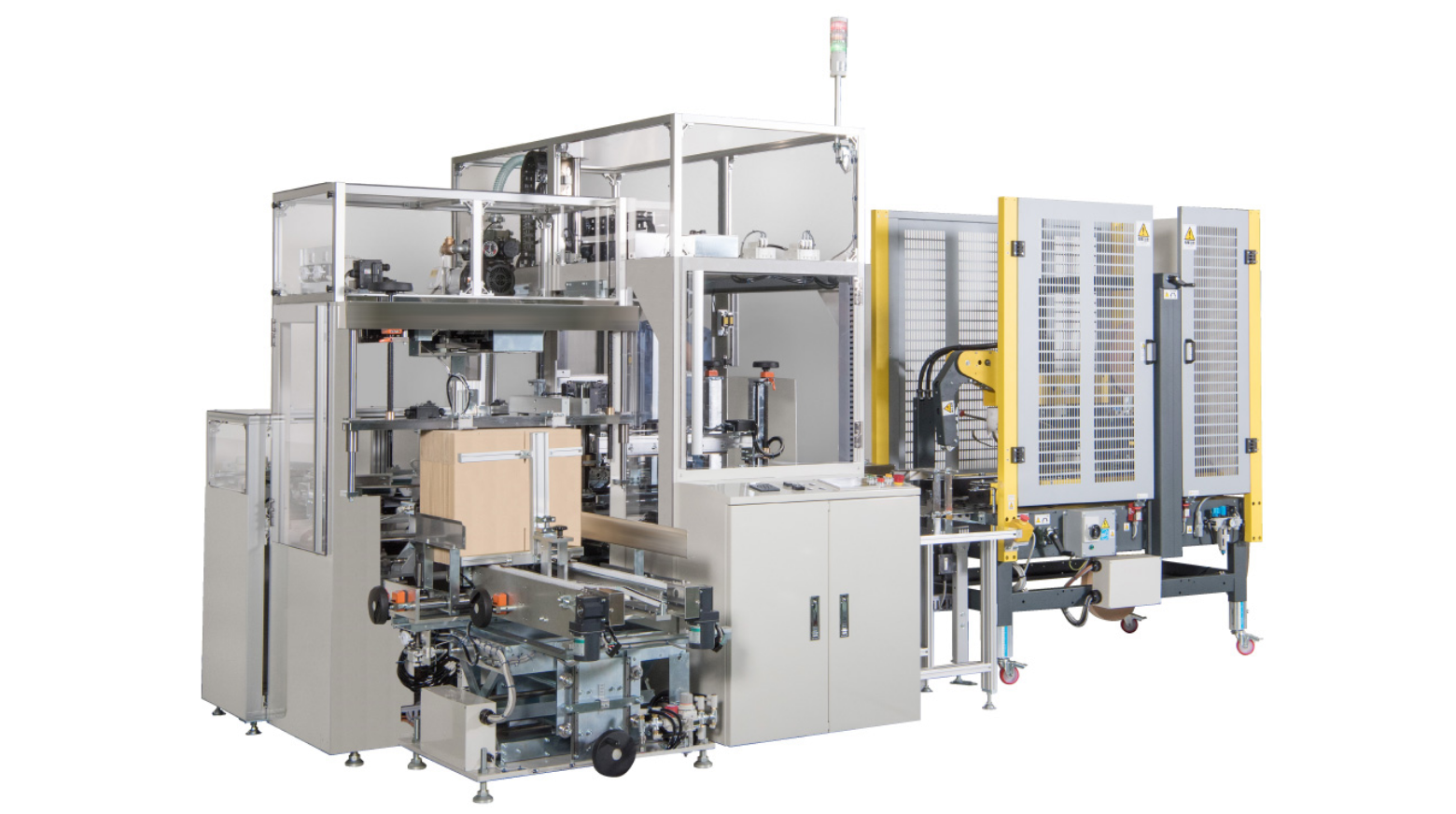

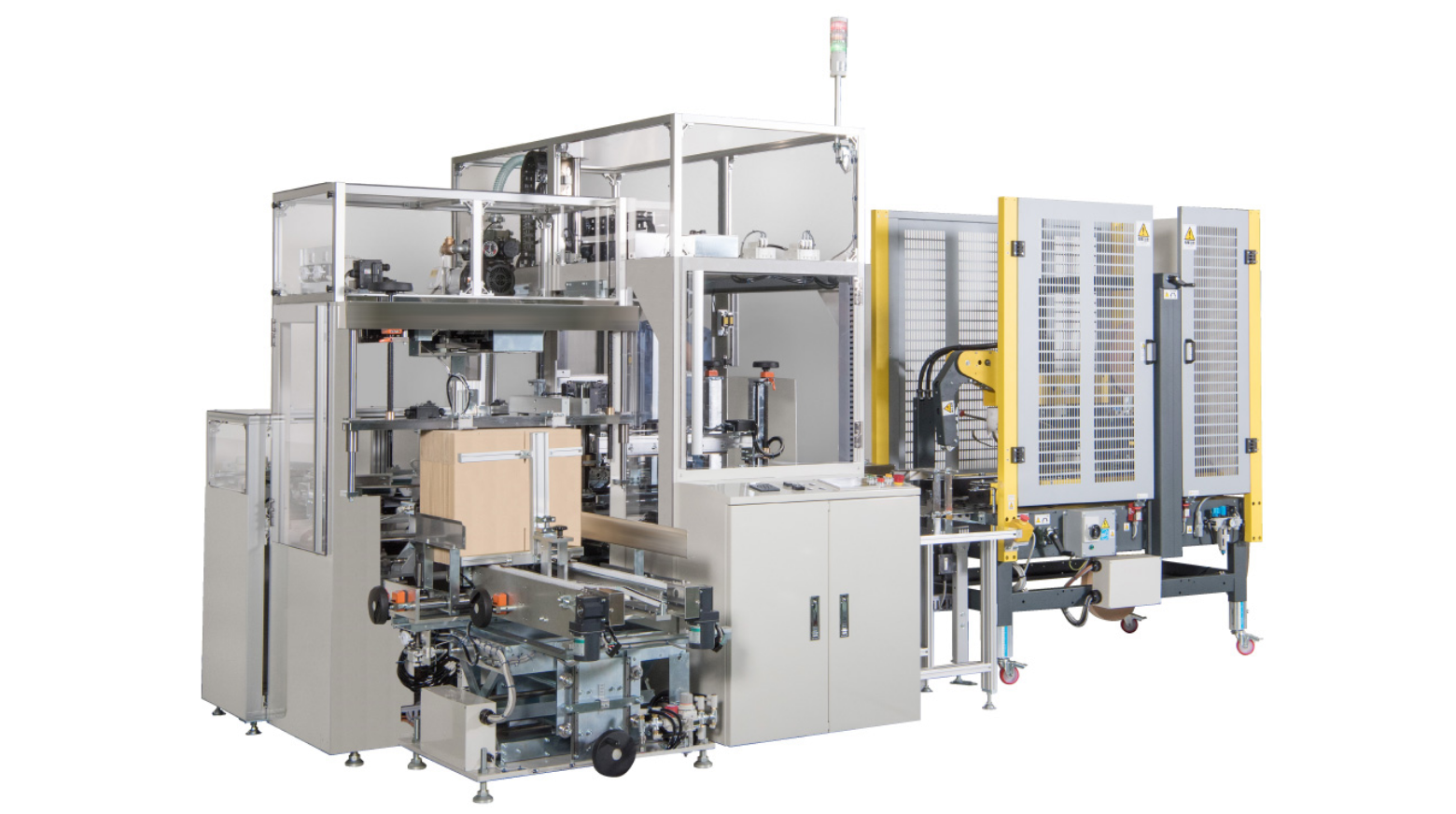

Casers

- A set-up cardboard caser for horizontal use of A-type corrugated cardboard.

- Simple and compact design.

- Downsized by reducing working distance of each operation.

- Improved performance and safety, easier operation and maintenance.

- Models for large cases are also available in the lineup.

DETAIL

Casers

- Compact top-open cardboard caser for vertical use of A-type corrugated cardboard.

- Combines with a collector for various product configurations, and automatically feeds products into cases.

DETAIL

Casers

- Wraparound cardboard caser for all types of collected products.

- Inclined case stocker for easy stocking.

- Standard-equipped pull-out mechanism minimizes sheet removal errors.

- Changeover handwheel with indicator enables repeatable setting for part size changes.

DETAIL

Casers

- A gluing and box making machine for large cartons that can handle a variety of box configurations, including tray, dust flap, and Charlotte.

- Absence of a single correct setting position facilitates line routing considerations.

- Mold replacement enables easy changing to different molds.

- Can also make boxes from blank cardboard sheets.

- Can connect to various types of product feeders in a single line configuration.

- Supply of accessories and incorporation of printing equipment also possible.

DETAIL

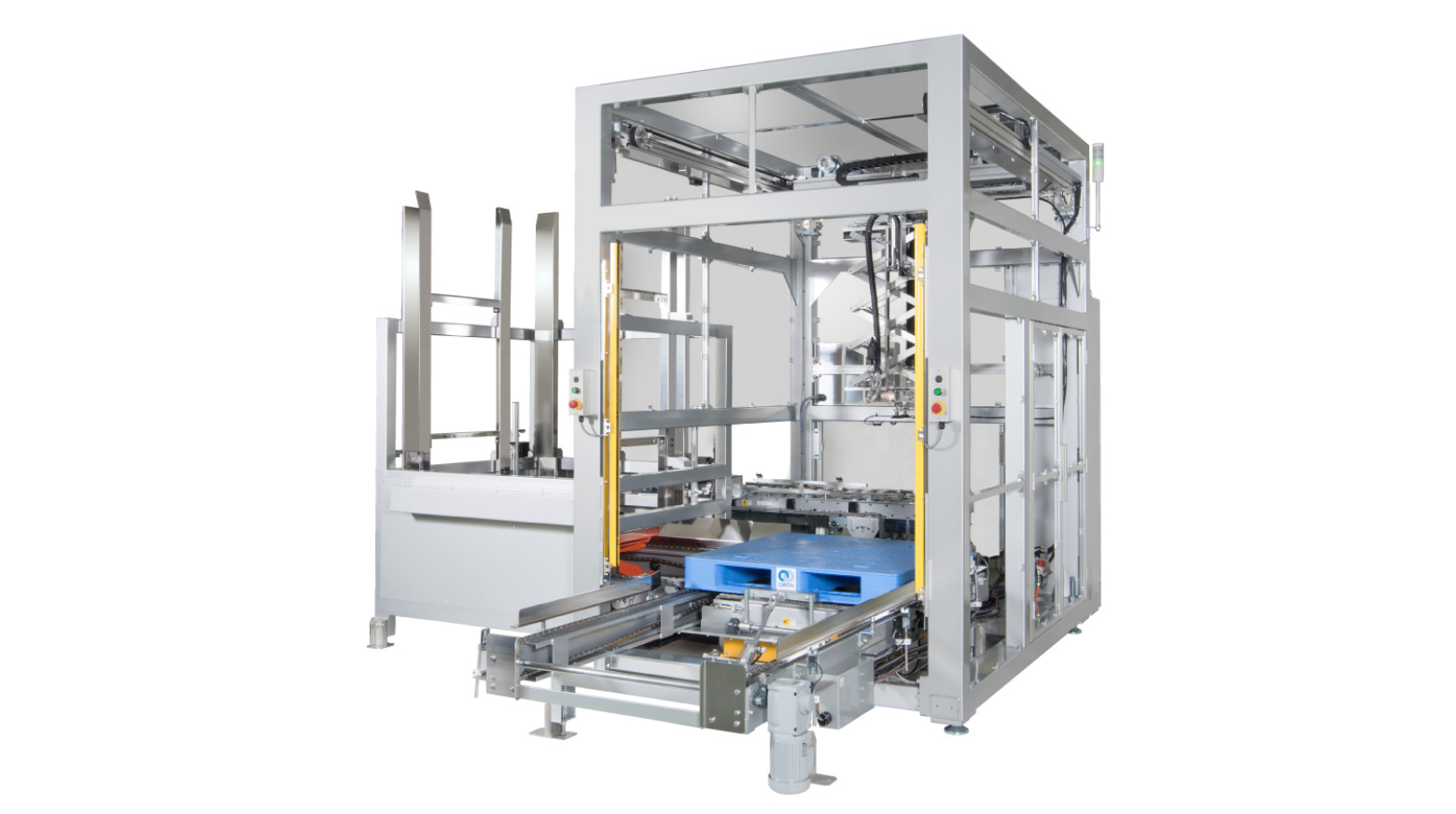

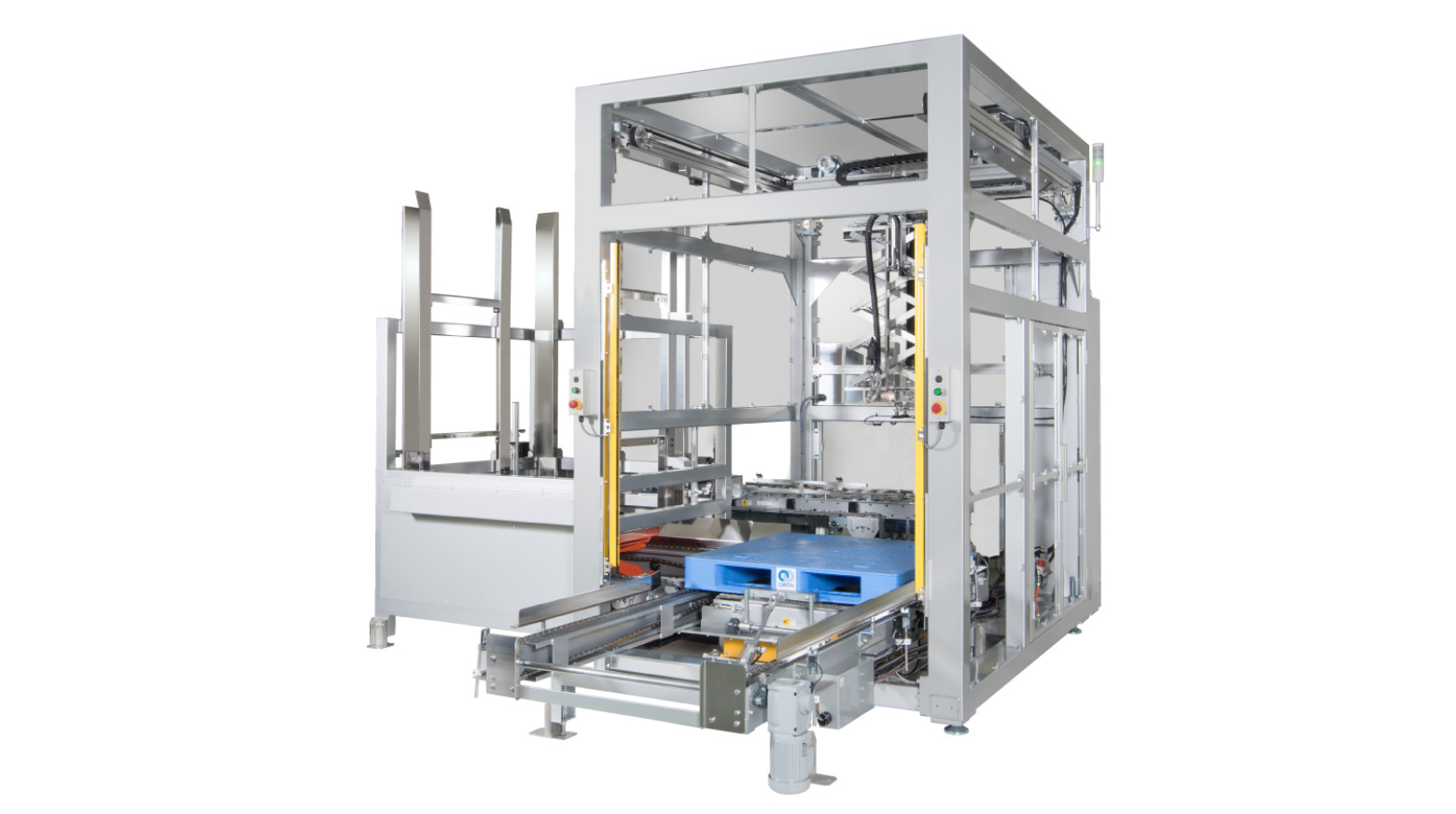

Robots

- Space-saving palletizer for stacking pallets of products packed in cardboard.

- The palletizer rotates one box at a time on the conveyor, and performs pinhole stacking (in variable patterns). Pallets are manually replaced when stacking is complete.

- The machine uses general-purpose parts as much as possible and is configured with a small number of parts.

- An automatic empty pallet changer can be installed as an option to automatically discharge actual pallets.

DETAIL

Horizontal Form-Fill-Seal Machines

Casers

Robots

Products

As professionals who handle the packaging process,

we offer the best packaging systems.